As the industry shifts more and more to non-entry cleaning methods, it is important to be able to predict what will happen inside equipment during cleaning. Young Group of Companies has stayed on the cutting edge of industrial cleaning by investing in a Fluid Dynamics Modeling (FDM) program. With the latest in Computational Fluid Dynamics (CFD) software and engineering expertise, fluid flow in industrial storage tanks is no longer a mystery.

The first step is to model the contents of the tank. The engineering team has compiled a database of over 100 varieties of crude oils, pipeline spec oils, diluents, and diluted bitumen to choose from as well as a wide variety of cutter stocks. If an oil is not in the database, all that’s needed is the specific gravity or density of the product, and all of the relevant fluid properties (viscosity, specific heat capacity, thermal conductivity) can be determined using advanced statistical models.

Next, the most effective cleaning method and the equipment required is selected based on the contents of the tank. Templates have been developed to be able to automatically select the most efficient pump and circulation tool. These templates also provide a cleaning time estimate and an “effectiveness check” to see if there is sufficient flow to reach the center of the tank and fluidize the bottoms.

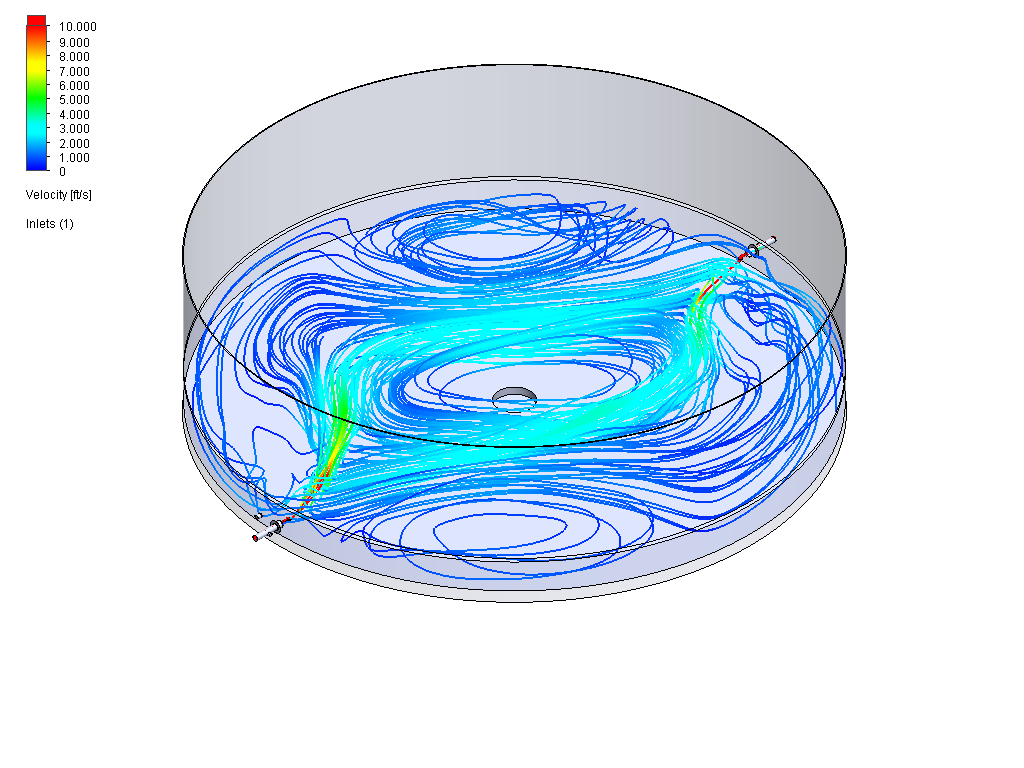

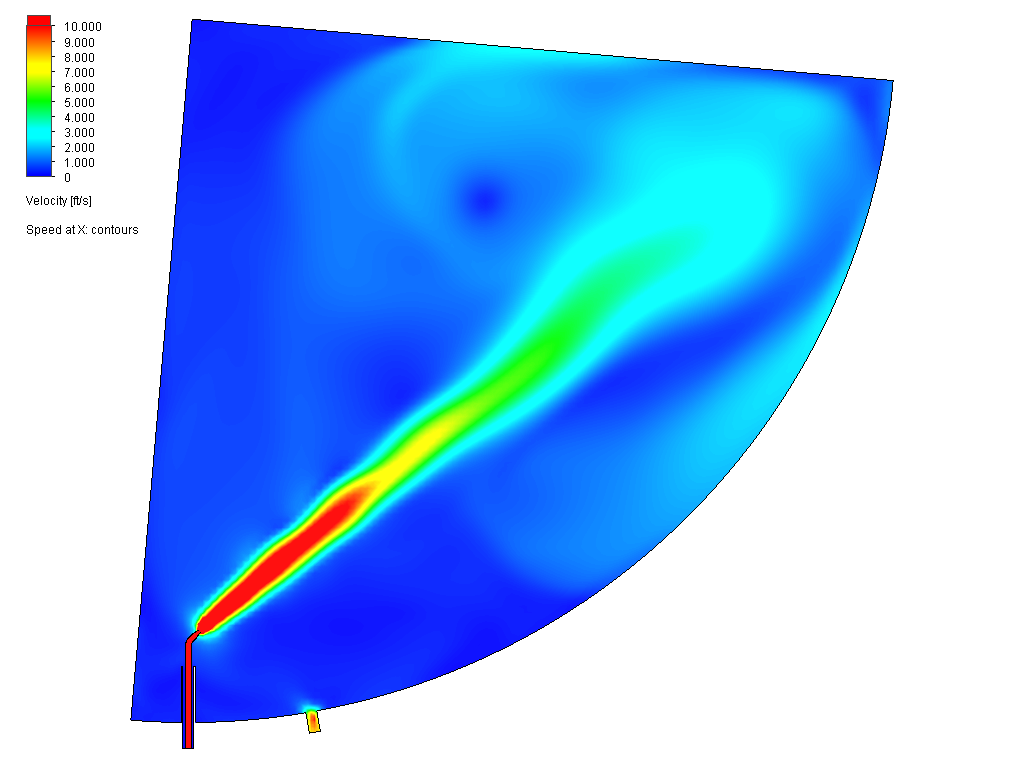

The results from the previous two models are then used for the CFD model of the tank. Further templates have been developed to be able to quickly create a solid model of a tank and run calculations using the latest in CFD software. With this software, it is easy to determine how the fluid will flow in any tank.

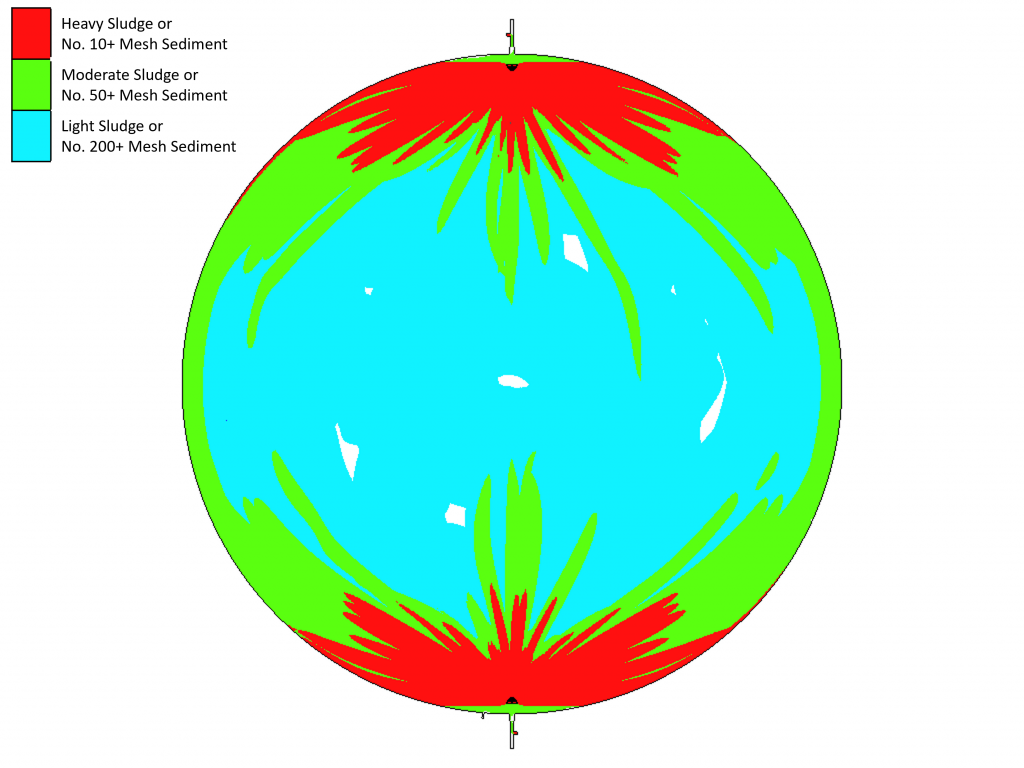

With tank circulation, there is no longer any guesswork as to whether or not the jet created from a sweep will reach the center of a tank or how much of the bottoms can be fluidized and suspended. The renders from these calculations can also help to show potential areas of concern where debris can settle and help to plan a final clean. Time-dependent and steady state calculations can be run on any size or shape of tank and can also help in creating ventilation plans or showing fluid flow during normal operation.

Young Group of Companies is always advancing, and the engineering team is hard at work developing new systems and processes to improve efficiency and performance. Currently, the team is applying environmental erosion research to modeling tank bottoms. This will help to provide a quicker and more accurate cleaning time estimate compared to earlier methods, as well as assist with the analysis of CFD calculation results.

For any fluid, any tank, and any cleaning method, determining what will happen inside a tank before cleaning begins is now possible thanks to the engineering team at Young Group of Companies.

Call today for a tank cleaning quote and ask for a fluid dynamics model.

403-517-2100

Share This:

CDN NEWS |

CDN NEWS |  US NEWS

US NEWS