By: Mel Larson

Equipment health is integral in an operating facility to obtain the highest performance; not just for a unit but across the whole plant. Equipment and system reliability is perhaps the most critical element of profitability. History shows that differences in operating expenses between best-in-class refineries and poor performers can be as much as $20-30MM/year so it’s accurate to say “Reliability equals Profitability.” Equipment health and reliability have multiple component parts across rotating equipment, fixed equipment, instrumentation, and infrastructural elements. Now is the time to take advantage of the COVID-19 impact by refreshing and updating systems to ensure a strong position for the future recovery.

There are various index rankings of internal segments of a company or structure that separate the parts without considering the whole. With all of the “systems” and digitalization engagements in place in the modern plant, it is important to remember that reliability remains the responsibility of the entire team. Reliability cannot solely depend on one system, group, or person. It is the responsibility of everyone.

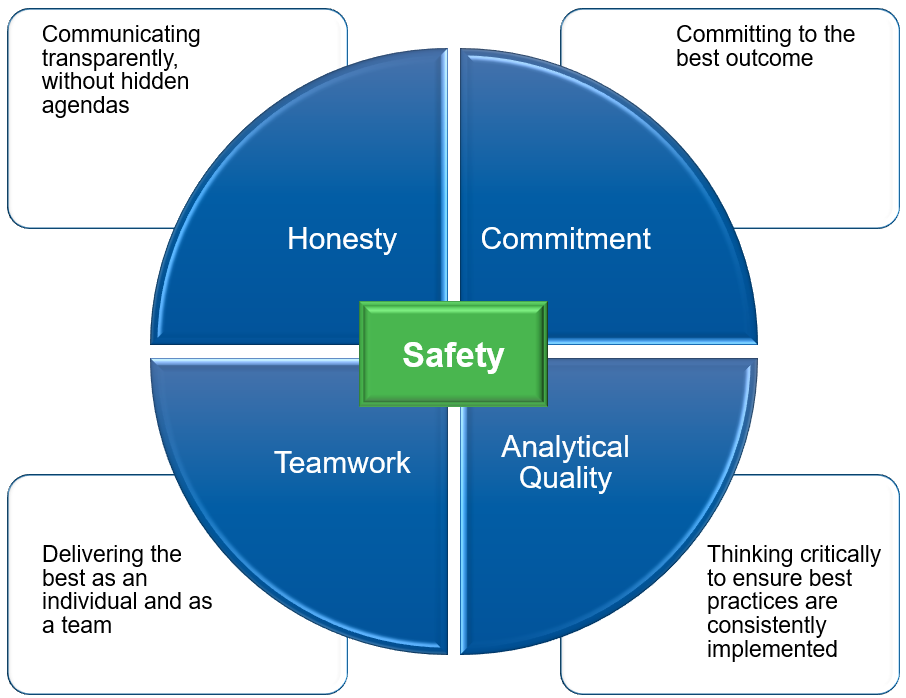

The industry uses the word reliability as a key tracking metric, but for most, reliability is a byword for safety. Reliability is a result of a successful “team” environment where process, operations, inspection, reliability and maintenance work together for the good of the people, plant and equipment. The diagram is a review the critical elements that make up reliability, and ultimately allow for safety in a plant.

Now let’s consider a problem element, such as a compressor. There will be data to review that includes process, vibration, power consumption, oil usage, and perhaps seal leakage data. The analytics will include a multidisciplinary team, which may include the manufacturer, to review the data in order to determine any corrective action or how to operate “more” appropriately. The key point here is that reliability is not a one-person job; it’s everyone’s job.

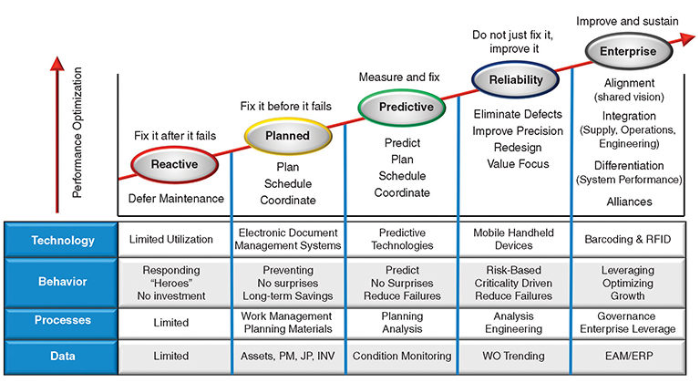

The industry utilizes instrumentation with data analytics as part of diagnostics to alert operations and the general mechanical groups of any potential issue. Good diagnostics through multidisciplinary teamwork (like a team of doctors) allows for a focus on corrective action. The real challenge is migrating from reactive to preventative to predictive actions using data not just as a tracking tool, but as an aid in adjusting attention and focus. Being proactive can be the difference between a plant “fall down” vs. a planned outage, which is much less financially impactful.

The collaboration and synergy of “muscle memory” (training with legacy knowledge) and good diagnostics can lead to real savings and improved profitability, and ultimately a safer workplace. Below are a few topics or areas to review in preparation for returning back to pre-COVID rates.

1. Cold Eyes Assessment (Self-evaluated or facilitated by an outside firm)

- What are the known and identified gaps?

- Be fearless to look inward for improvement

- Critical equipment care list updated and maintained

- Action list developed and prioritized to close the known gaps

- Is there an “evergreen” refreshing of people and processes to remain competitive and with current industry best practices and procedures?

- Muscle memory is not confined to operations, i.e., knowledge is necessary across the teams taking advantage of legacy input (past), while embracing the tools and systems to move forward (predictive)

If you rate your company honestly based on the amount of work that is completed in each of these categories by percentage, you will likely notice that a large amount of your capital is being spent reactively. Instead of waiting for problems to appear, why not spend more up front to ensure asset reliability, and ultimately improve the safety and efficiency of your plant?

2. Focus maintenance on reliability with preventative work activities.

- Analyze wrench time and systems to improve what is lacking

- Encourage skill set reinforcement to ensure work and craft effectiveness

- Review bad actor analysis as identified areas to address

- Review known corrosion program(s)

- Conduct fixed equipment health analysis

- Analyze rotating equipment condition and care

3. Turnaround planning

- Review of past “discovery” areas

- Early identification of critical elements

- Right skills with correct program schedule

- Correct sequence

- RBWS along with inspection or metal loss reviews

- Can the planned work be executed,

Becht has experts in all equipment disciplines as well as trained reliability professionals who can assist your facility in the implementation of effective programs. These efforts have significantly improved reliability, safety performance, and production for our clients in a variety of plants.

Becht can help evaluate the conditions in your plant and help drive the systems and culture to improve reliability. We have over 1500 experts in the refining, nuclear, and petrochemical industries. Most Becht experts are from owner organizations and have 30 plus years of experience.

Please contact us if you have any questions or are looking to improve the health of your assets for a safe, reliable, and profitable future.

Share This:

CDN NEWS |

CDN NEWS |  US NEWS

US NEWS