Plan for the 2022 winter season – optimize operational safety and water heating costs in winter conditions during your completions program.

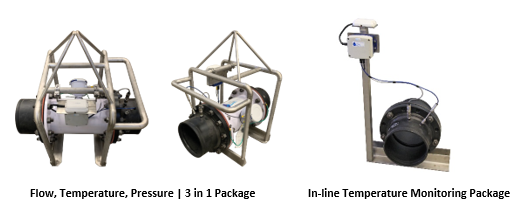

Water heating costs are a significant component of completions budgets during the winter season but even in these challenging conditions, there is still an ability to optimize costs through real-time temperature measurement, agile field response, and transparent reporting to the producer. Random Acronym, in partnership with Jadler Industries, has developed a remote hardware and software solution that allows for the continuous monitoring of critical waterline data:

- Flowrate and cumulative volumes

- Pressure and pressure profiles

- Temperature and temperature profiles

- Temperature and level of water in Aboveground Water Storage Systems (AWSS)

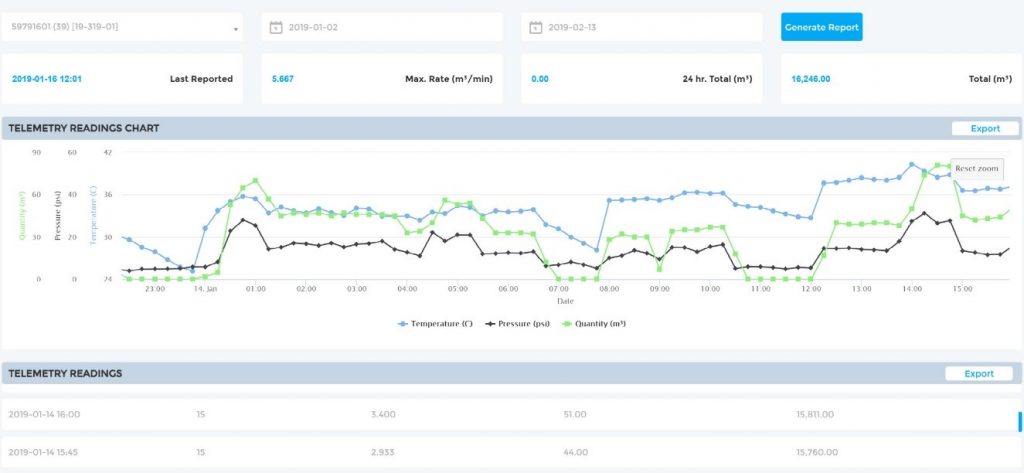

Real-time data is collected and provided to stakeholders through Random Acronym’s FieldTrackerTM data management platform, allowing water transfer and heating service providers to respond to operational demands on the fly while ensuring transparency in costs with their clients, both at the field level and remotely.

FieldTracker has enabled dozens of operators to optimize their water transfer operations year-round but has the added advantage of supporting safe operating conditions and keeping heating costs in check during challenging winter conditions.

FieldTracker can be utilized with inline temperature probes to monitor water temperatures during surface water transfers. The real-time monitoring and analysis allow for a significant reduction in fuel consumption and optimizes winter heating programs. The system provides additional safety measures in that producers can avoid risks associated with pigging, or a burst line, because of the live insight on operational conditions and understanding of when and where ice might form. This type of application for water heating takes the guesswork out of knowing how much heat to apply to water conveyance operations for hydraulic fracturing. The ability to determine optimal heating setpoints allows for the reduction in fuel consumption when using superheaters, significantly reducing costs and emissions, as well as enables field personnel to be actively aware of heating operations and maintain a safe working environment in the winter.

Velvet Energy, one of the early adopters of FieldTracker in the Canadian upstream oil and gas industry, implemented the digital technology in 2018 at their Gold Creek asset. Guillermo Guglietti, Water Advisor at Velvet, explains how FieldTracker played a key role in optimizing their completions program:

“Random Acronym’s technology allowed us to automatize the remote data collection and gain real-time visibility of our temporary water operations. The data, which used to be collected manually and delivered to us by our vendors, became an integral part of our water management strategy. Real-time water operations data has allowed us to effectively manage risk, reduce fuel consumption and emissions by tailoring our heating and pumping activities; and ultimately, avoid costly service interruptions on our water supply. In essence, their platform has brought affordable and fit-for-purpose technology to the water management space, becoming as part of this process a silent yet essential contributor to overall operational cost savings and the reduction of environmental footprint on water operations across many companies.”

The success of Velvet Energy is a compelling case study because it demonstrates how operational safety, cost savings, and environmental improvements can be achieved simultaneously with a technological solution. With FieldTracker, the old reactive approach to water transfer is replaced with a proactive approach that provides confidence and agility in the field, with the ability to relay real-time data for improved operational and environmental risk mitigation – ultimately resulting in cost optimization and a positive impact to the bottom line.

Contact us today to discuss how FieldTracker could bring operational improvements and cost savings to your completions program.

Marlon Fleming, Bsc.

Director

Random Acronym

403.801.9124

[email protected]

www.random-acronym.com

Brad Smith, CPA, CA

President

Jadler Industries

403.690.8603

[email protected]

www.jadler.ca

Share This:

CDN NEWS |

CDN NEWS |  US NEWS

US NEWS