Detecting airborne hydrocarbons including methane, hydrogen and other fugitive emissions within seconds of exposure.

Revolutionizing Engine Safety with ShockerEDGE

As a leader in the global energy sector, your commitment to safety is paramount. With ShockerEDGE, you have the opportunity to set a new standard in industrial safety. ShockerEDGE is the first and only technology of its kind, specifically engineered to protect your workforce, operations, and your reputation.

- No docking stations

- Automatic calibration

- Proactive detection

- Innovative safety solutions

Methane Detection You Can Trust

ShockerEDGE is a cutting-edge solution specifically designed to meet the unique needs of the energy sector, particularly for organizations like yourself that prioritize safety and environmental stewardship. ShockerEDGE can detect and specifically call out methane and hydrogen if it is detected, and it can be installed in any combustion engine, ensuring it is equipped to identify fugitive emissions across all facilities, ensuring real-time monitoring and rapid response to potential leaks. This innovative technology not only enhances operational efficiency but also aligns with the important commitment to minimize environmental impact and adhere to regulatory standards regarding methane emissions.

By integrating ShockerEDGE into every plant vehicle you can proactively safeguard its workforce and facilities. Continuous monitoring allows for the immediate detection of all major gas leaks, significantly reducing the risk of hazardous situations. As plant vehicles traverse the site throughout the day, ShockerEDGE serves as a vital tool in maintaining safety protocols, ensuring that any methane emissions are addressed before escalating into serious issues. This comprehensive approach not only enhances the safety of the team but also reinforces a dedication to sustainable practices in the energy sector.

What is ShockerEDGE?

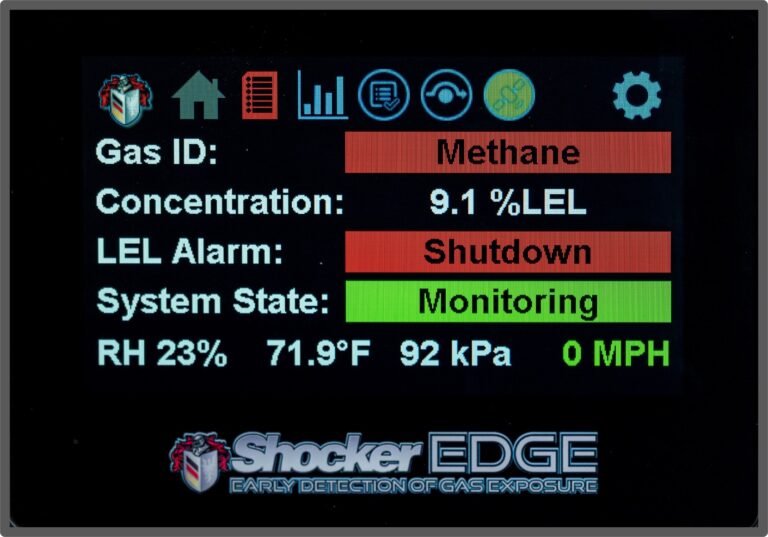

ShockerEDGE is an advanced safety device designed to be installed in any internal combustion engine. Unlike anything currently on the market, this innovative technology utilizes a molecular properties spectrometer to analyze the incoming ambient air. If any dangerous gases, specifically airborne hydrocarbons (LEL), are detected, ShockerEDGE will immediately warn the operator that there are hydrocarbons at 0.1% to 7.49%, and then shut down the engine when above 7.5% LEL, preventing potential disasters before they can occur.

Key Features:

FIRST-OF-ITS-KIND TECHNOLOGY:

ShockerEDGE is the first and only device that integrates a molecular properties spectrometer directly into internal combustion engines, providing continuous gas monitoring.

NO ADDITIONAL EQUIPMENT NEEDED:

No need for docking stations, calibration, bump gas, or instrument technicians. ShockerEDGE recalibrates automatically, making it a hassle-free solution.

NORTH AMERICAN MADE:

Designed and manufactured entirely in North America with the highest quality standards. Each unit is rigorously tested before shipping.

LONG-TERM RELIABILITY:

Built to last with high-quality materials, ensuring durability and longevity even in challenging environments.

AUTOMATIC SHUTOFF:

Detects airborne hydrocarbons (LEL) in ambient air and automatically warns you then shuts off the engine to prevent dangerous situations before they occur.

CONTINUOUS DIGITAL CALIBRATION:

Calibrates every two seconds, adjusting for temperature, pressure, and humidity, ensuring reliable operation across different environments.

REGULATORY COMPLIANCE:

Set to 7.5% LEL, ShockerEDGE meets and exceeds industry regulatory requirements in both Canada and the United States, ensuring maximum safety.

PROACTIVE DETECTION:

Alerts operators to gas leaks before they exit the vehicle, reducing the risk of exposure and enhancing overall site safety.

EQUIVALENCY WITH POSITIVE AIR SHUTOFF VALVES:

The ShockerEDGE can replace or work alongside positive air shutoff valves. It has received a 5 year equivalency certificate from Transport Canada.

Leading the Future of Safety with ShockerEDGE

With the ShockerEDGE, your business can lead the charge in redefining industrial safety standards. This revolutionary technology not only protects your operations but also solidifies your position as an industry leader in safety and innovation. By adopting ShockerEDGE, you won’t just be meeting standards – you’re setting them.

Why ShockerEDGE is Essential for Your Business

Have you ever stepped out of your vehicle only to have your personal monitor start going off?

With ShockerEDGE you don’t need to worry about putting yourself or others at risk. You’ll know if there are flammable gases in the area before you even open the door of your vehicle.

- Enhanced Operational Safety: By integrating ShockerEDGE across your facilities and job sites, you can drastically reduce the risk of engine-related incidents caused by dangerous gas leaks. This device acts as an always-on guard, ensuring that your engines are turned off before any hazardous situation develops.

- Simplified Compliance: With ShockerEDGE set above industry regulatory requirements, you can ensure compliance with Canadian and U.S. safety standards effortlessly. This means fewer manual checks, reduced downtime for compliance testing, and a stronger safety record.

- Become a Safety Innovator: Implementing ShockerEDGE positions your business as a leader in industrial safety innovation. This proactive approach to safety not only protects your workforce but also reinforces your brand’s commitment to excellence and responsible operations.

How Your Business Can Implement ShockerEDGE

- Widespread Integration: Deploy ShockerEDGE across all of your facilities on stationary and mobile equipment, especially in areas with high risk of gas exposure such as drilling sites, refineries, and transportation hubs. Every plant vehicle can be equipped with a ShockerEDGE for site-wide detection. This will provide a blanket of safety that ensures any detected leaks are addressed immediately.

- Strategic Deployment in High-Risk Zones: Focus the initial implementation in zones that are identified as high-risk for gas exposure. This targeted approach allows for a phased rollout while immediately addressing the areas of greatest concern.

- Training and Awareness: Incorporate ShockerEDGE into your safety training programs. Ensure that all personnel are aware of the device’s functionality and the increased safety it provides, fostering a culture of innovation-driven safety.

Share This:

CDN NEWS |

CDN NEWS |  US NEWS

US NEWS