Client: Major Petrochemical Operator – Alberta

Scope: Pigtail (small-bore) welds beneath legacy hydrogen furnace

Conditions: Catalyst remained in tubes, requiring extreme caution and minimal heat spread

Problem with Traditional Method: Rigid ceramic elements obstructed the weld area, required excessive insulation, and posed a risk of heat bleed

Challenge:

A critical maintenance scope called for welding pigtails beneath a hydrogen furnace, a task complicated by several key factors:

The furnace was built in the 1960s, with limited access and non-standard geometry Catalyst remained loaded in the tubes, eliminating any margin for error on temperature control or heat bleed.

Traditional ceramic-style resistance elements had to be bulked up with blankets and board insulation, adding clutter and increasing safety risk.

These rigid systems also obstructed weld visibility, slowing down fit-up and arc time. The client needed a low-profile, precision heating solution that could reduce risk, improve access, and accelerate setup under tight shutdown windows.

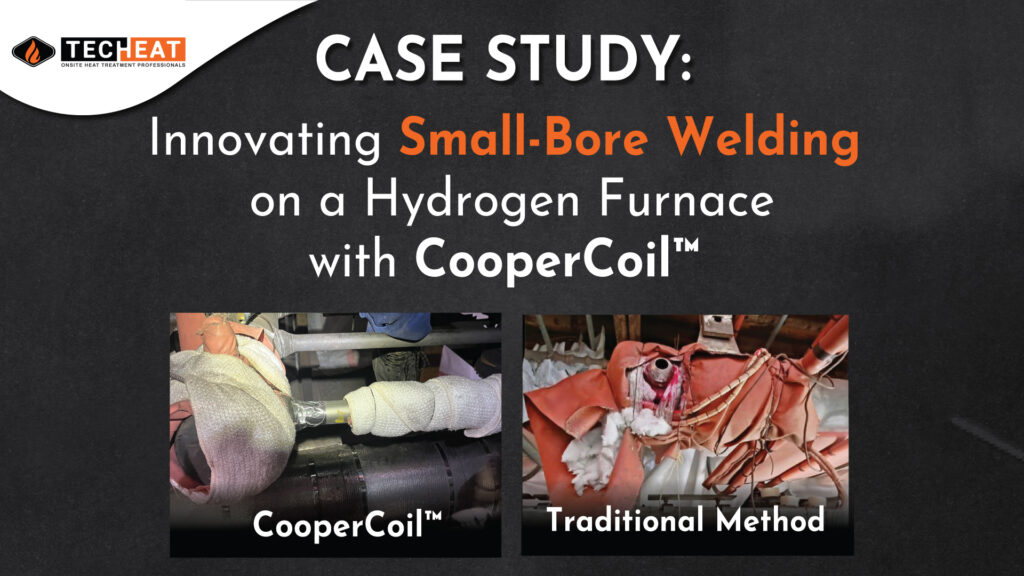

Traditional Method Overview:

Bulky Ceramic Pads: Required extensive ceramic fiber wrap and hard insulation

Heavy Setup: Time-consuming and inflexible on tight furnace geometry

Poor Weld Access: Elements sat directly in the welder’s line of sight

Heat Bleed Risk: Harder to control localized preheat without affecting nearby catalyst-filled tubes

CooperCoil™ Solution:

Flexible Braided Element: Wrapped directly around small-bore without interfering with torch access

Low-Profile Design: Enabled direct weld access even in tight, low-clearance spots.

Targeted Heat Application: Localized heating ensured critical temperature control without radiating excess heat.

Rapid Setup: Cut installation time by over 60%, minimizing non-productive labor waiting on preheat.

Cleaner Workspace: No need for extra blankets or board to “build up” insulation, the CooperCoil™ did the job cleanly and efficiently.

Measured Results:

Conclusion:

For one of the most delicate small-bore weld scopes imaginable, working beneath a catalyst-loaded hydrogen furnace, CooperCoil™ proved to be a breakthrough solution. Its compact form, precision heating, and welder-friendly design helped the client complete a high-risk scope safely, efficiently, and ahead of schedule.

CooperCoil™ continues to demonstrate that better heating starts with better design.

Client Feedback:

“We were impressed with how clean and efficient the CooperCoils were. With the catalyst still in the tubes, we needed to be confident in the heat control—and your team delivered. Setup was fast, the work area stayed open, and the welders weren’t fighting with insulation the whole time. We’d absolutely use this system again.”

—Execution Lead

To learn more about how CooperCoil™ and our heat treatment services can elevate your next project, contact us through our website, by phone, or at one of our locations across Canada.

Technical Heat Treatment Services Ltd. (TECHEAT)

www.techeat.com | +1 888-658-0699 | [email protected]

Share This:

CDN NEWS |

CDN NEWS |  US NEWS

US NEWS