Rotating equipment is the heart muscle of industry and lubricating oil is the life blood. When lubricants fail, machines break down and your process grinds to an expensive halt!

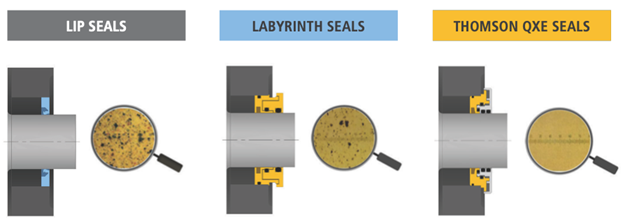

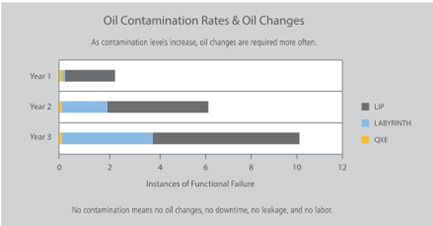

Eighty two percent of mechanical failure is due to particle contamination. The good news is that with limited points of ingress, this problem can easily be overcome with the right seal. Since most contaminants enter through a failed bearing oil seal. The traditional lip seal arrangement only has an effective life of 3,000 hours before its integrity drops.

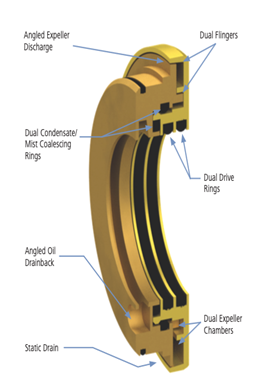

The Thomson QXE Bearing Isolator combines proven labyrinth technology with an innovative expeller design to eliminate shaft wear and oil leaks, prevent contamination and increase equipment uptime.

Only 10% of bearings ever reach their design life before failing or being replaced.

Tap the sealing power of labyrinth design and the new QXE technology. The QXE is a true, non-contact bearing isolator, utilizing double vertical internal chambers.

Centrifugal force adds energy to contaminants, deflecting them away from your housing while effectively retaining lubrication.

Two static internal coalescing O-rings exclude vapor ingress by breaking it down and directing it to the contamination exclusion chambers. And the QXE can be split for ease of installation.

Save on:

Thomson QXE Bearing Isolator features:

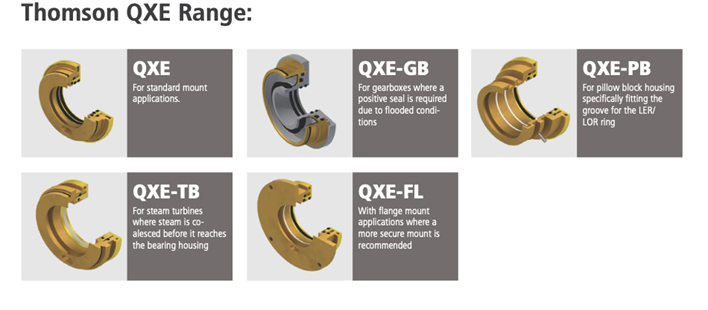

The highly adaptable QXE design can be used in many applications and scenarios, from regular pump-bearing housings to gearboxes, pillow blocks, and steam turbines. It is the perfect solution to many instances of lubricant contamination.

QXE maximizes bearing life by uniting proven labyrinth design with new QXE technology.

Thomson QXE: Keeps contaminants out and lubrication‑increasing Mean Time Between Failure (MTBF) by Maximizing Bearing Life. Call a subject matter expert at: 780.450.8080.

Share This:

CDN NEWS |

CDN NEWS |  US NEWS

US NEWS