The inefficiencies weren’t obvious to management.

Like many others, the oil producer was managing distinct functional areas with the usual service providers, all with their own systems.

It was a logical separation of duties. After all, it’s the status quo, even for some of the leanest energy firms.

But by bringing in Oplii, an operations management platform that connects the office and the field with industry-leading mobility, the company soon realized massive savings, efficiencies and improvements.

Let’s take a look at their top four returns on investment.

1. SLASHING OPEX

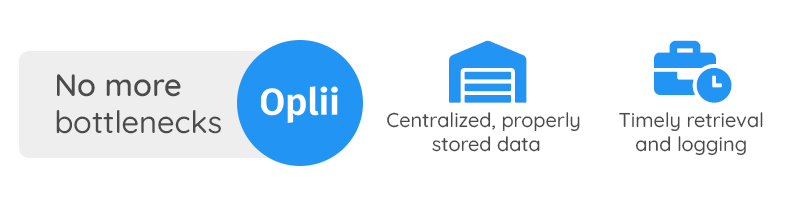

Previously, asset integrity, asset and MOC data were housed in fragmented databases. With Oplii, these were consolidated into a single system.

This meant the producer could end service agreements with three external providers, resulting in clear-cut savings of more than $355,000 per year.

2. WORKFORCE EFFICIENCY

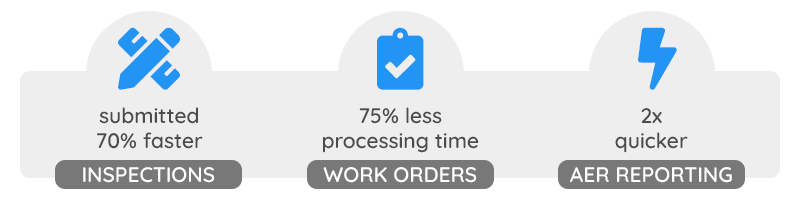

Rolling out Oplii Mobile for work orders and inspections resulted in 70-75% time savings in the submission of work. This replaced the traditional pen-and-paper method, eliminating the need for scanning and transcribing.

Regulatory reporting processes, like producing AER deliverables, were cut in half.

3. CONTINUOUSLY IMPROVING DATA

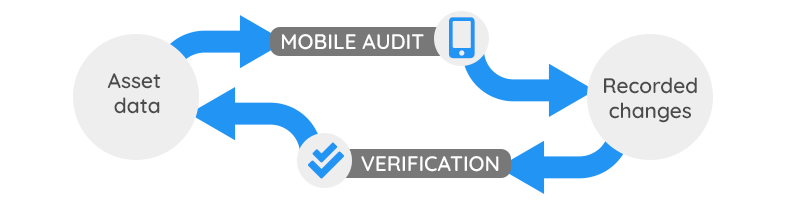

While Oplii halves the time it takes the producer to audit assets, it also assists in the creation of a more accurate, up-to-date database.

Using Oplii Mobile, data collected by auditors is piped back into the asset database via a feedback loop. A verification process acts as a safeguard to ensure unwanted changes aren’t made. The end result? A one-stop shop for precise, authenticated data.

And when it came to collected inspection data, readings and other results were no longer housed in PDFs, meaning data could be reported on for the purpose of detecting and forecasting trends.

4. GREATER CONTROL

The company was not happy with how its data was being managed by external vendors. Every time a change or report was required, they’d be waiting days for PDFs and spreadsheets. And sending data into those system took days, if not weeks.

By bringing asset integrity and other data in-house, the company was able to eliminate the lag times associated with accessing its own data, as well as gain greater access and control.

CONCLUSION

This producer has been using Oplii for several years now and remains a very happy customer. They’ve recently started using additional modules and tools, such as NCR processing and configurable workflows for MOC and maintenance, as well as rolling out more and more inspections to field operators.

For more information on Oplii can help your organization, visit www.oplii.com or call 1-888-994-9337.

Oplii is a proudly Canadian company leading the way in operations management software for O&G.

The Oplii enterprise platform is powerful and easy to use, and includes integrated solutions for the management of assets, asset integrity, maintenance, HSE, MOC, NCR and more – with industry-leading proprietary mobile tools that truly connect the office and the field.

Share This:

CDN NEWS |

CDN NEWS |  US NEWS

US NEWS

COMMENTARY: Where the Fight Against Energy Subsidies Stands – Alex Epstein