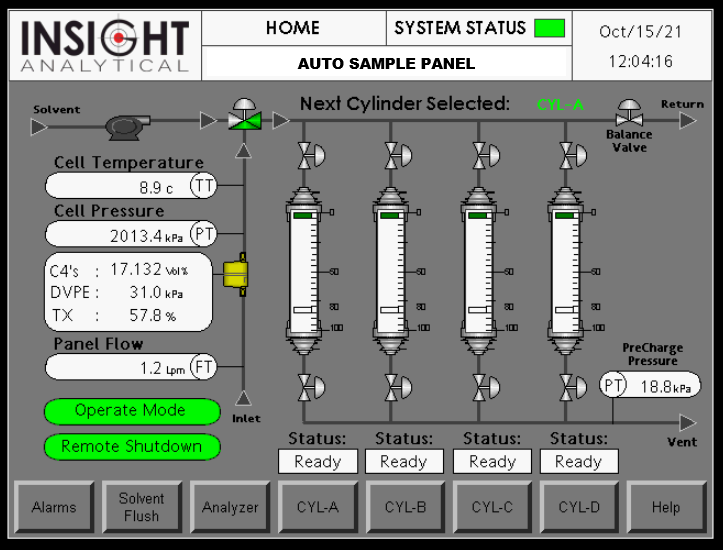

Common issues with sample systems can include plugging, sample collection and user unfamiliarity. With our smart sample systems data is pulled in real-time and distributed in a networked approach. We use a cellular modem to provide remote monitoring and diagnostics capabilities. User configurable HMI’s put process data at an Operators fingertips, this can make a significant difference in safety for the operation and maintenance of our systems. We provide custom HMI screens – Alarms, Trends, and Data Capture all to ensure maximum efficiency and compatibility with process conditions. Our systems allow for automatic & manual sample collection where applicable – including automatically generated barcodes & Chain of Custody information. As experts in Sample Condition design and implementation we regularly include features such as automatic & manual solvent flush sequences to ensure maximum uptime of our systems. We can provide several methods of communication back to plant controls including Modbus TCP/IP and RS-485. Our sample systems are designed to help eliminate error in process measurement when precision is what matters.

Ask us for information on how we can help maximize your process while improving safety and reliability!

Summary

- Data is pulled in real time and distributed in a networked approach

- Cellular capabilities for remote monitoring & diagnostics

- User configurable HMI’s put process data at your operators’ fingertips

- Eliminate error when precision matters

- Make work safer for operations & maintenance

- Automatic/Manual Sample Collection & COC generation

- Automatic/Manual Solvent Flush systems

- Custom Alarms, Trends and Data Capture

- Modbus via TCP/IP or RS-484

Share This:

CDN NEWS |

CDN NEWS |  US NEWS

US NEWS