See More from ENERGYminute HERE

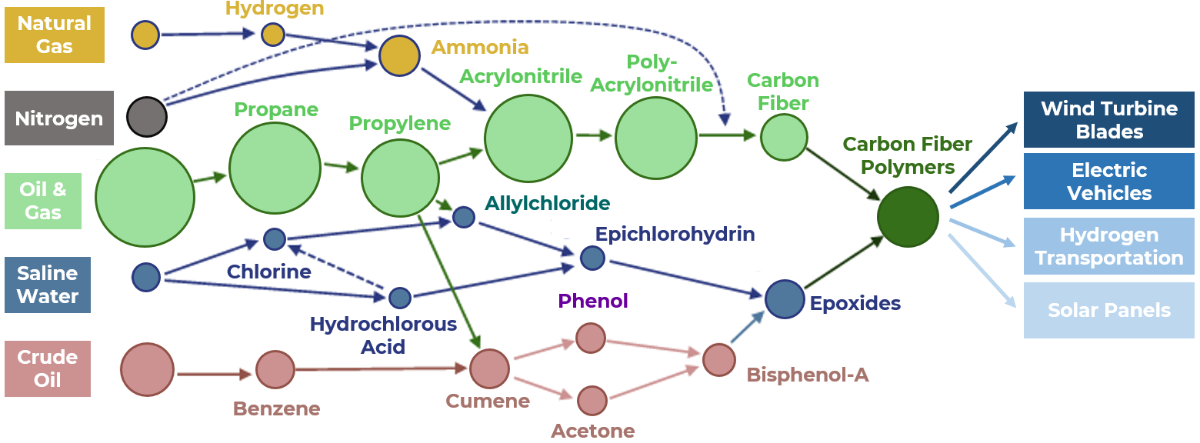

Inputs and uses of carbon fiber

bubble size denotes usage per ton of carbon fiber polymer

Courtesy of Thunder Said Energy

Carbon fiber is a material 3 to 10 times stronger than steel but 70 to 80 percent lighter. In an age with a need to maximize energy efficiency and conservation, a material that does more with less is truly a miracle material. Along with being the structural component of wind turbine blades, carbon fiber is used in fuel-efficient vehicles, electric vehicles, hydrogen transportation, and solar panels.

- On the less miraculous environmental side, 30 tons of carbon dioxide are created for every ton of carbon fiber polymer.

At the center of the material is the ‘carbon’ from hydrocarbons, particularly oil and natural gas, which are key inputs into its fabrication.

The upside: The use of carbon fiber easily pays for itself energy-wise, returning back its energy costs 20 to 200 times. A little bit of oil and gas to make the polymer reduces a lot of energy consumption on the backend.

The downside: Efforts to decarbonize carbon fiber is a catch 22: decarbonizing it will increase costs by 70 to 100 percent, which then inflates costs of other decarbonization technologies which use it. Being one of the largest components to wind turbines, a decarbonized carbon fiber would significantly increase the price of wind power.

Share This:

CDN NEWS |

CDN NEWS |  US NEWS

US NEWS

COMMENTARY: Busting Biases, Boosting Innovation – Geoffrey Cann