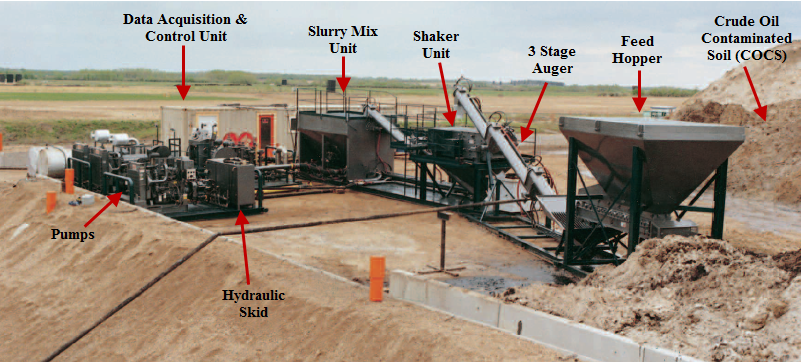

Terralog Technologies Inc. has developed the Slurry Fracture Injection (SFI) process as an advanced deep well disposal process for upstream petroleum industry waste streams. The SFI process is a field-proven Zero-Discharge waste disposal technology used extensively around the world for more than 20 years site remediation of oilfields and disposal of E&P waste streams. SFI is being used to permanently dispose of large volumes of wastes such as crude-oil contaminated soil (COCS), sludge, NORM, drilling waste, produced solids, and produced water. Millions of barrels of these waste streams have been safely disposed in the petroleum sector with the Terralog SFI process. The SFI technology is ideal for site remediation during decommissioning of upstream assets.

Are you looking to decommission your inactive oil & gas wells and achieve a rapid, economic and environmentally sustainable site remediation program? Terralog is looking for a well site in Alberta, BC, and/or Saskatchewan to utilize a mobile SFI service for injection-disposal of COCS and other waste streams generated during well abandonment and site reclamation.

The proposed solution is a mobile SFI service to inject and dispose of COCS (and other wastes at the well site area) into an actual well at the reclamation site; and then the disposal well can be abandoned at the end of the job. This approach can lead to significant cost reduction and time reduction in the remediation and surface reclamation work at each well or cluster of wells. This is ideal for existing orphan wells or inactive wells destined for P&A operations.

Mobile SFI Service Benefits:

- Rapid deployment service to remediate wellsites scheduled for decommissioning.

- Time reduction in the disposal work at each well – expected 3-4 days/well site.

- Eliminate the costs and HSE risks associated with waste transportation.

- Zero-discharge waste disposal process with no need for landfilling or long-term waste storage.

- Reduced environmental impact on the biosphere.

- Significant cost reduction in the disposal work at each well.

- If multiple wells in the area (well cluster) cost can be further reduced by use of a centralized disposal facility for a cluster of wells.

- Facilitates a rapid site reclamation process and conversion back to farmland or targeted land use.

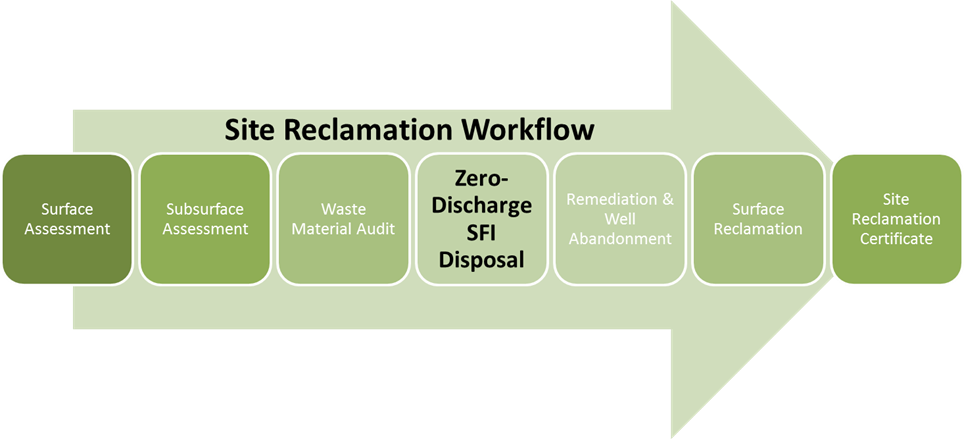

The mobile SFI service can be easily integrated into a robust wellsite abandonment program for Zero-Discharge waste disposal of COCS and other related waste streams, as follows:

If you are interested in this opportunity, please contact:

Maiy Latif, P.Eng.

Terralog Technologies Inc.

[email protected]

+1 403 216 4730

About Us:

Terralog Technologies Inc. (TTI) is a service company headquartered in Calgary, Canada and specializing in the development and implementation of innovative technologies for sustainable energy resource development. TTI’s area of expertise is Clean Energy Geomechanics.

The TTI technology portfolio includes:

- Advanced Deep Well Disposal: Slurry Fracture Injection (SFI) is a proven zero-discharge disposal solution for large volumes of waste streams in the petroleum industry, including drilling waste, production waste, contaminated soil, oily viscous sludge, and NORM/TENORM contaminated waste streams.

- Unconventional Resource Development: Slow & Easy hydraulic stimulation is a cutting-edge technology for enhanced hydrocarbon production and significantly reduced environmental impact in unconventional plays.

- Clean Energy Geomechanics: Renewable energy storage, CO2 geological sequestration, gas storage mechanics, compaction & subsidence studies, geomechanics numerical modelling, and technical courses in geomechanics.

TTI’s services are ISO-certified and built on extensive experience in geomechanics, geology, fracture mechanics, and environmental management with practical field experience. For more information, please visit www.terralog.com.

Share This:

CDN NEWS |

CDN NEWS |  US NEWS

US NEWS

COMMENTARY: Markets Call Trump’s Bluff on Russian Oil Sanctions in Increasingly Risky Game – Bousso