Be confident of compliance, while minimizing on assist gas

Flaring – regulatory compliance

Regulatory pressure to minimize flaring is intensifying.

Properly operated flares achieve at least 98% combustion efficiency. However, calorific values less than 270 BTU/SCF will not assure 98% destruction efficiency on flaring1. In these cases it is necessary to add supplementary fuel, e.g. natural gas. In a permit review case, if the heating value of the emission stream is too low and no supplementary fuel has been added, the application is considered unacceptable. To operate a flare properly, continuous monitoring of the calorific value is therefore required.

The WIM Compas keeps you compliant – with a record of accurate calorific value measurements from a system designed to remain reliable with minimum maintenance in these harsh environments.

Plant efficiency

Flare gases are increasingly blended into fuel gas systems, to be burned. Besides the elimination of waste, flares are an important element of safety systems. Non-waste gas released during an upset condition is typically combusted in a flare system.

The calorific value of the flare gas is a measure of the amount of energy wasted – a determinant of overall plant efficiency. Some operators report their flare emissions in terms of wasted energy.

Flare gas composition generally fluctuates widely and frequently. Therefore, if slow-response measurements such as Gas Chromatography are used to determine calorific value, a buffer of natural gas will be required.

The fast measurement response of the WIM Compas allows operators to reduce assist gas consumption while remaining compliant.

Instrument selection and installation

The following are key criteria in selecting an analyzer

- Wide dynamic range: As the flare is used as a safety device, the flare gas composition can change widely. If low values are expected and the measurement is required to control the blending of back up gas, it is mandatory that the analyzer can measure down to zero. Hobré WIM COMPASTM analyzers use an electrically-heated (catalytic) oven for burning the sample – no flame out errors occur.

- High dew point at low pressures: typically a liquid knockout vessel is installed upstream of the actual flare stack. Consequently, the flare gas can be saturated with water and / or hydrocarbons. As flares are operated at low pressures, the need for a pump should be avoided as water and HC’s can condense by elevating the pressure. The WIM COMPASTM system works at pressures as low as atmospheric, and is available as High Temperature version which can be heated to 150°C (300°F).

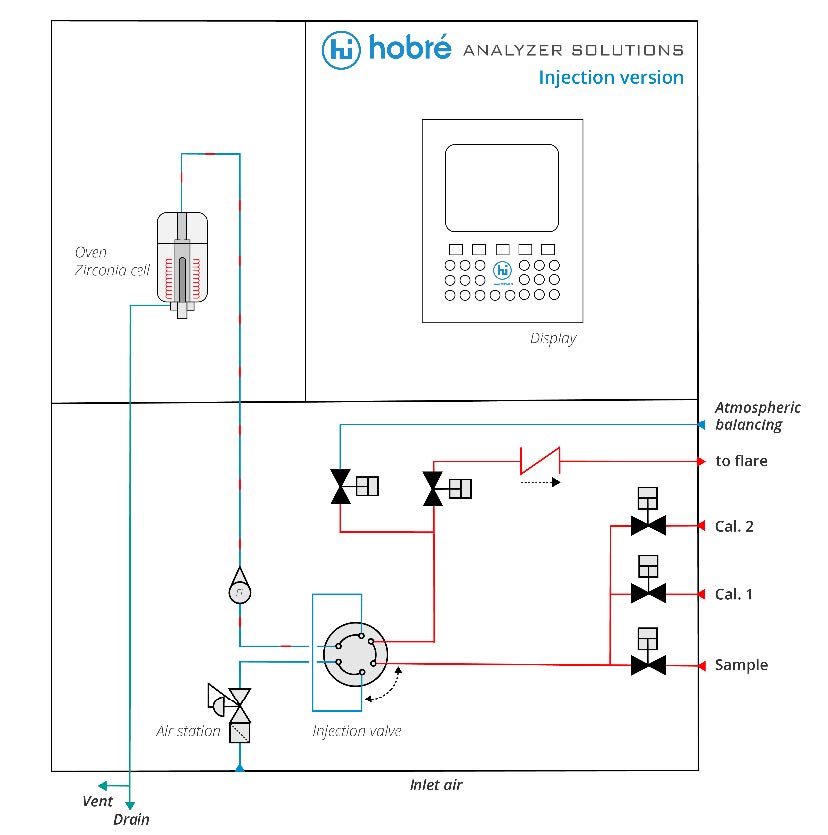

- Corrosive / toxic components, for instance H2S, are likely to be present in flare gas. When combusted H2S causes serious corrosion / clogging to the internals of the analyzer. Acid condensate (sulfuric acid) will be formed when the flue gas condensates (H2O in combination with SO2/SO3). The Hobré WIM COMPASTM for flare gas applications, injects very small amounts of gas in a carrier of instrument air. Due to the relatively large excess of air, no condensation after combustion will occur and corrosion / clogging issues are prevented.

- Local venting of gas should be prevented: besides the environmental effects, flare gas is likely to contain toxic elements causing safety issues. The WIM COMPASTM F is set up as Zero HC emission unit. Excess gas can be returned to flare, for instance by using an eductor or pump.

- For safety reasons, flares are typically installed in remote locations. For this reason the measurement equipment must be installed at these (hazardous) locations also. The WIM COMPASTM, is suitable for outdoor installations. No expensive shelter with HVAC is required.

Hobré Instruments has delivered WIM COMPASTM for flares with the goal of minimizing natural gas consumption at many locations. It can be installed in hazardous areas – ATEX, IECEX, CLASS 1 DIV 2, KCS, TR-CU/EAC, PESO/CCOE and INMETRO (approval pending).

More Information

The WIM COMPAS™ adds to Hobré’s portfolio of process analyzers for measuring Wobbe Index, Heating Value/BTU, Combustion Air Requirement Index (CARI), Air Demand, Specific Gravity and Mol Weight. The Wobbe Index and/or Heating Value are critical parameters used to optimize blending and combustion processes. Designed and manufactured in-house, the WIM COMPAS™ builds on Hobré’s experience with residual oxygen type analyzers. The analyzer is considered a market leader in the oil & gas industry.

To learn more about the Hobré WIM COMPAS™ please visit Westech Industrials website at https://lnkd.in/gAg–Nj or call and speak to one of our local representatives at 1-800-912-9262.

Share This:

CDN NEWS |

CDN NEWS |  US NEWS

US NEWS

COMMENTARY: Where the Fight Against Energy Subsidies Stands – Alex Epstein