Data is only valuable if it can be accessed, transformed, and understood. This is especially true in the energy sector, where data collection, processing, and operational improvements have long been core practices. From advanced process control to high-fidelity digital twins built using thermodynamic models, the industry has continuously leveraged technical ingenuity to overcome operational challenges. What’s changing today is the immense computing power now available and the expanding vision of what’s possible.

However, realizing this vision requires a clear understanding of business goals to chart the best course forward. Economic pressures, regulatory compliance, occupational safety, and market conditions all present key areas where digital transformation can drive impact. The challenge lies in identifying which data is most valuable and ensuring it is actionable.

The Challenge of Extracting Value from Data

According to a PwC report titled Drilling for Data: Digitizing Upstream Oil and Gas, “the use of digital technologies in the upstream sector could cut production costs by up to 20% and result in cumulative savings of US$100 billion to $1 trillion in CAPEX and OPEX by 2025.” These savings stem from improved maintenance strategies, optimal asset utilization, supply chain optimization, and integrated technology platforms that leverage advanced analytics. More companies are recognizing the power of automation to reduce costs, increase efficiency, and improve safety and compliance.

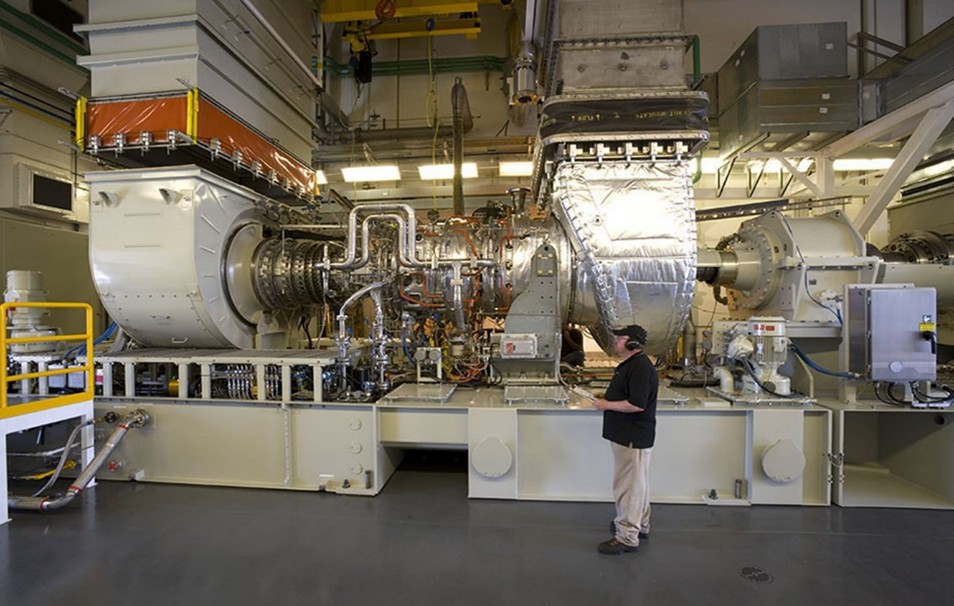

Gas Turbine Generator

However simply implementing data focused solutions without a clear strategy can lead to data overload and misinterpretation. Additionally, two other requirements are critical. First, it’s critical to understand the data origins and have a single source of truth. Analytics on bad data yield bad results. Second, understand the applications that will be bring value and what data will answer questions. There’s an old axiom in statistics: “If you torture the data enough, it will confess to anything.” This is a real risk in data-driven decision-making, where spurious correlations can lead to misleading conclusions.

Next, Identifying the right technologies to collect and process the relevant data is essential. For example, a robust historian plays a crucial role in this ecosystem, enabling efficient data collection at both the local operational and corporate levels. By organizing and storing real-time and historical data, a historian ensures companies have access to accurate information for advanced analytics and decision-making. A well-designed data infrastructure allows organizations to extract meaningful patterns, optimize processes, and generate real value. Integrating advanced analytics, machine learning, and real-time data processing tools, further enhances operations and can create a competitive advantage.

Targeted Solutions for Immediate Impact

For many companies, one approach is not an enterprise-wide overhaul, but targeted digital transformation initiatives focused on specific applications, processes, or functions. These smaller-scale improvements act as foundational building blocks, driving momentum for broader digital adoption across the enterprise. They’re easier and more cost effective to implement, create value and thus increase adoption

One Example. Reliability-centered maintenance (RCM) is a corporate-level maintenance strategy that helps organizations optimize their maintenance programs to ensure that equipment maintenance is performed efficiently, safely, and cost-effectively. The goal of RCM is to maximize equipment availability while reducing the need to replace assets.

RCM is a customized methodology that defines maintenance for each asset differently depending on its specific needs. It involves the execution of a structured methodology to identify critical assets and develop effective maintenance plans for each. RCM includes a thorough analysis of each asset’s failure modes, criticality, and overall impact should a failure occur. The analysis considers the equipment’s purpose, performance requirements, and impact on the overall system. Analysts also consider how the equipment can fail to perform its main function, the causes of each failure, and the impacts of each failure on the system. Finally, it is important to consider how to prevent or minimize the impact of each failure, and what actions to take if a failure cannot be prevented. The result of an effective RCM program is the implementation of a specific maintenance strategy for each critical asset, whether reactive, planned, or predictive. The overall result is a better operation with improved safety and reduced costs.

It all starts with the right data being available in a form that allows for insights to be derived. By strategically implementing targeted solutions, organizations can achieve immediate benefits while laying the groundwork for a scalable, enterprise-wide transformation. When integrated into a cohesive digital strategy, these drive long-term efficiency gains, cost reductions, and better operations.

Tarco’s extensive experience in project delivery has provided deep insights into data and its transformative potential for operations. Our services help companies navigate the complexities of data collection and compilation, define KPIs, and ensure that decision-makers have access to the right information at the right time. By aligning individual digital initiatives within a broader enterprise framework, organizations can gradually evolve toward a fully optimized, data-driven operation.

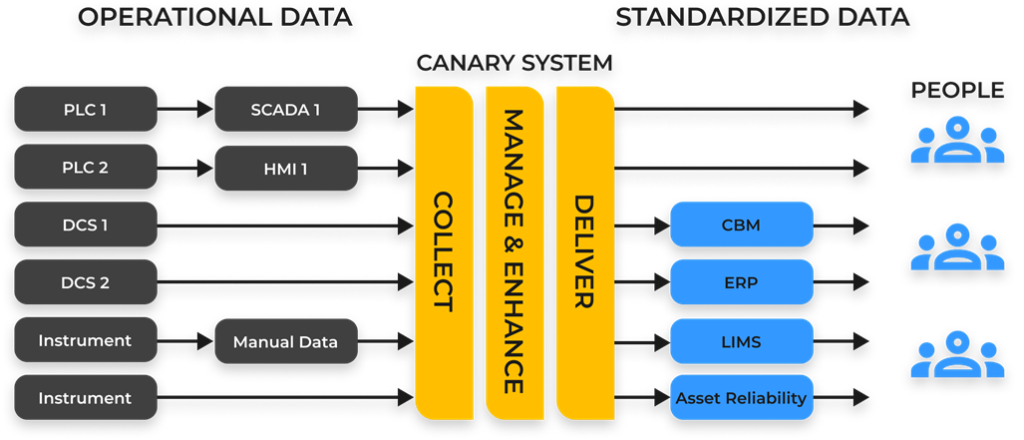

The Canary System

Credit: Canary, Canary System Data Collection, Transformation and Delivery Process Flow

As a system integrator, Tarco partners with technologies vendors including Canary Labs to support customers and a bring data solutions to the energy sector. Canary Labs offers the Canary System, a high-performance real-time data collection, storage, analysis, and delivery solution. At the core of which is the Canary Historian, which efficiently reads, stores, and writes millions of data points at unparalleled speeds. Complementing this is Canary Views, a tool that creates a virtual representation of underlying data, allowing clients to navigate assets with well-structured and meaningful tag names and asset contexts. These capabilities empower companies to gain both real-time and historical insights into equipment and process performance.

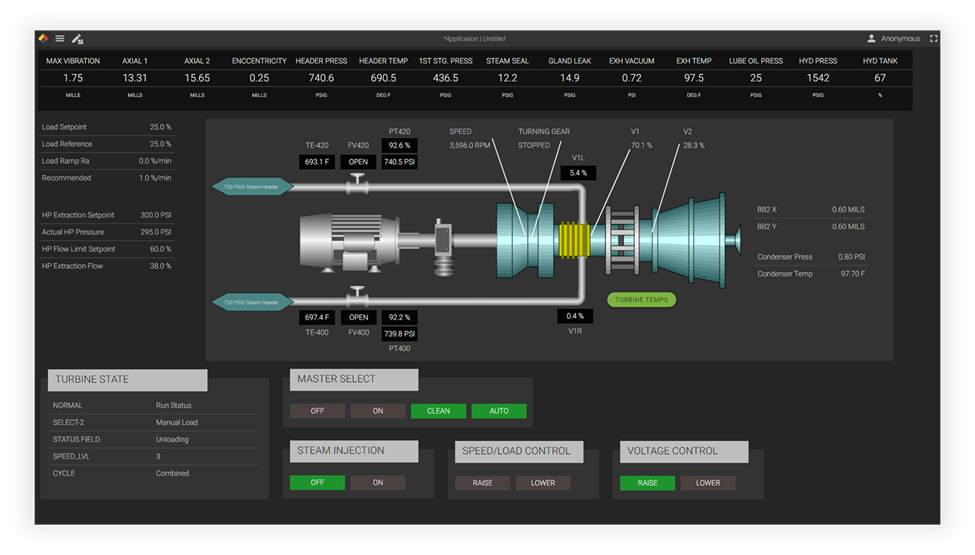

Gas Turbine Generator Performance Overview built with Canary’s Axiom Graphical Web Client Application

By leveraging the right digital tools, energy companies can drive efficiency, reduce costs, and achieve new levels of operational performance. The future of our industry lies in the intelligent use of data—and with the right strategy, the possibilities are limitless.

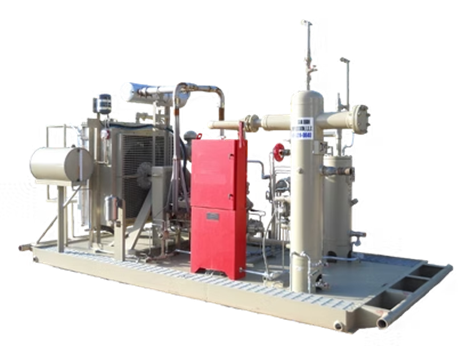

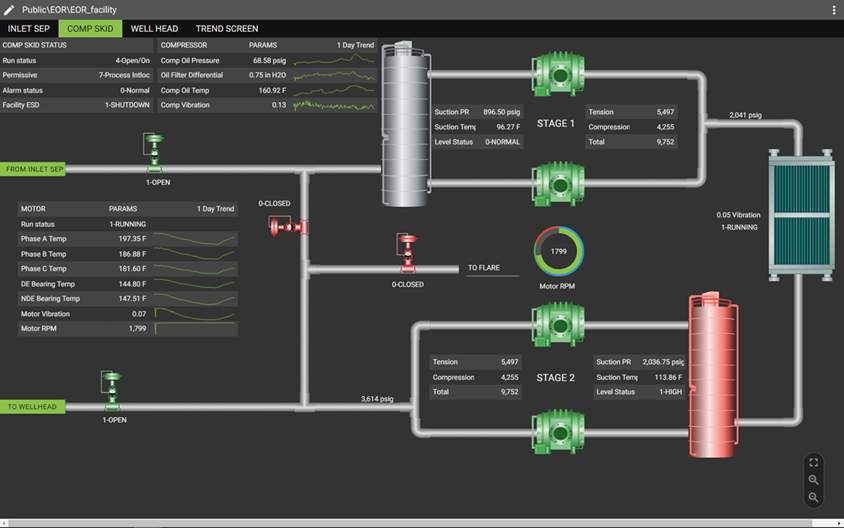

Typical Well Head Compressor Skid

Well Head Compressor Skid Performance Dashboard built with Canary’s Axiom Graphical Web Client Application

Share This:

CDN NEWS |

CDN NEWS |  US NEWS

US NEWS

COMMENTARY: Trump’s Big Bill Shrinks America’s Energy Future – Cyran