The Current State of Diesel Fuel Cost in the Oil & Gas Industry

Diesel fuel is essential to the oil and gas industry, powering everything from drilling rigs to vehicles. In recent years, the cost of diesel has fluctuated dramatically, often in response to global economic conditions and the changing market for crude oil.

There has been a significant increase in the cost of diesel fuel over the last year. The main driver of this increase has been the rising cost of crude oil used to produce diesel fuel.

Several factors can affect the price of diesel fuel. For example, the cost of diesel can be influenced by the strength of the U.S. dollar, as diesel is often traded in dollars on the global market. Changes in global demand for diesel can also affect the price, as can geopolitical events and natural disasters that can disrupt the supply of crude oil and diesel fuel.

The increased cost of diesel fuel has had a ripple effect throughout the oil and gas industry, with many companies struggling to maintain profitability in the face of higher fuel expenses. Some companies have responded to the higher fuel costs by implementing cost-saving measures, such as reducing the number of drilling rigs in operation or switching to more fuel-efficient vehicles.

Despite the recent increases in diesel fuel costs, the oil and gas industry remains an essential contributor to the global economy. Many countries rely on the production of oil and gas to meet their energy needs, and the industry provides jobs and income for millions of people around the world. As such, the cost of diesel fuel is likely to continue to be a major concern for the industry in the coming years.

Enter Hydrogen Injection

Hydrogen injection technology is a method that can be used to reduce the amount of fuel needed to power internal combustion engines. The technology involves injecting hydrogen gas into the air intake of an engine, which can improve the engine’s efficiency and reduce its fuel consumption. The science behind the technology has been known since the late 1970s.

For oil and gas companies, using hydrogen injection technology can help mitigate the impact of rising diesel fuel prices. By reducing the amount of diesel fuel needed to power their engines, companies can save money on fuel expenses and potentially improve their profitability. In addition, hydrogen injection technology can help companies reduce their carbon emissions, which is an increasingly important concern for the oil and gas industry.

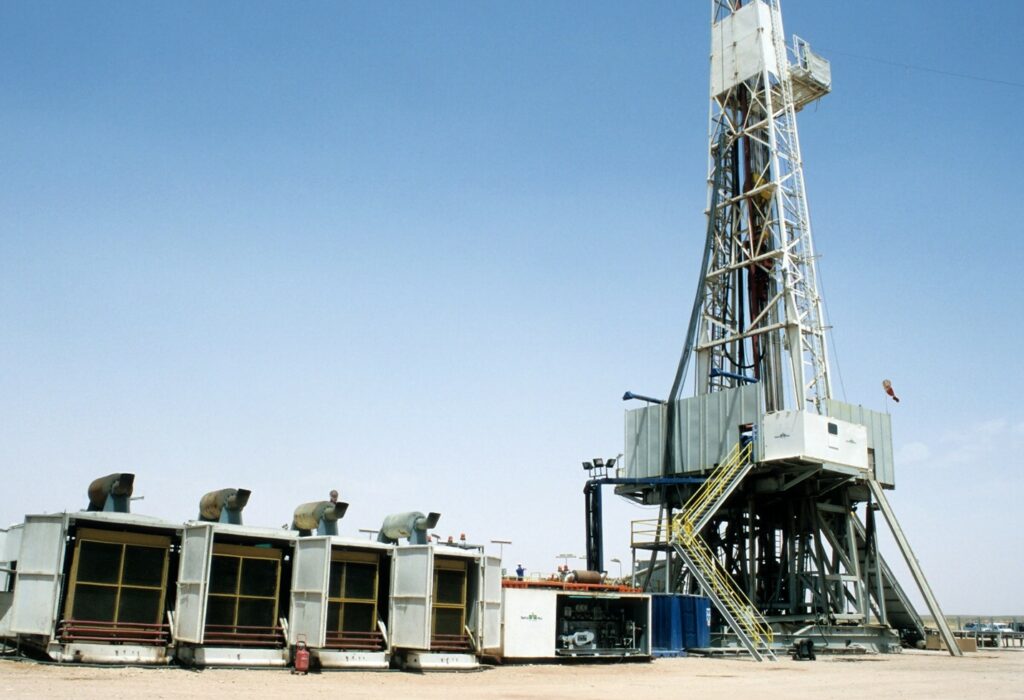

There are several ways that hydrogen injection technology can be used to reduce fuel consumption in the oil and gas industry. For example, the technology can be used to power drilling rigs, which are typically powered by large diesel engines. By injecting hydrogen into the air intake of the engines, companies can reduce the amount of diesel fuel needed to operate the rigs, potentially saving significant amounts of money on fuel expenses.

Hydrogen injection technology can also power vehicles in the oil and gas industry, such as transport trucks. In this case, the technology can help to reduce the amount of diesel fuel needed to power the vehicles, which can again result in significant cost savings for companies.

Overall, hydrogen injection technology can be an effective way for oil and gas companies to mitigate the impact of rising diesel fuel prices and improve their profitability. By reducing fuel consumption and emissions, the technology can help companies operate more sustainably and efficiently in an increasingly challenging market.

The Most Cost-Effective Hydrogen Injection Technology Companies Can Implement Immediately

Although the science has been widely known for over four decades, with environmental concerns as front-page news in recent years, the use of hydrogen has gained more notoriety and acceptance. The largest barrier to entry of hydrogen, however, has been the enormous capital cost of changing fueling infrastructure (transportation, storage, etc.).

Since 2010, Hydrogen Plus has enabled customers to utilize their existing diesel engine assets to save fuel costs and make a positive environmental impact while not incurring any of the expensive infrastructure costs. Their patented Incremental-Partial Hydrogen Injection (I-PHI), a bolt-on “Hydrogen-on-Demand” system, creates hydrogen by utilizing only small amounts of distilled water.

Average fuel savings, depending on the application, is 20%.

Even carbon credits are available on each I-PHI installation. Every installation comes with a fully certified ISO 14064-2 “Green Print Assessment”, which calculates the emissions saved and credits earned. This is another added benefit for companies wanting to maximize earned carbon credits and raise their ESG profiles.

With hundreds of successful installations, the Hydrogen Plus technology is proven in the field. Data from a recent installation shows a return on investment in as little as 2 months.

To find out more about how Hydrogen Plus can help your company’s profitability, please contact Tom Kaptian – [email protected].

Share This:

CDN NEWS |

CDN NEWS |  US NEWS

US NEWS