Is there a digital twin in your future? As more companies in the energy industry adopt digital twins to manage their essential assets, it’s worth examining this trend and the value it delivers. Digital twins help engineers, technicians, and operators better understand how their complex assets are performing now and how they will perform in the future.

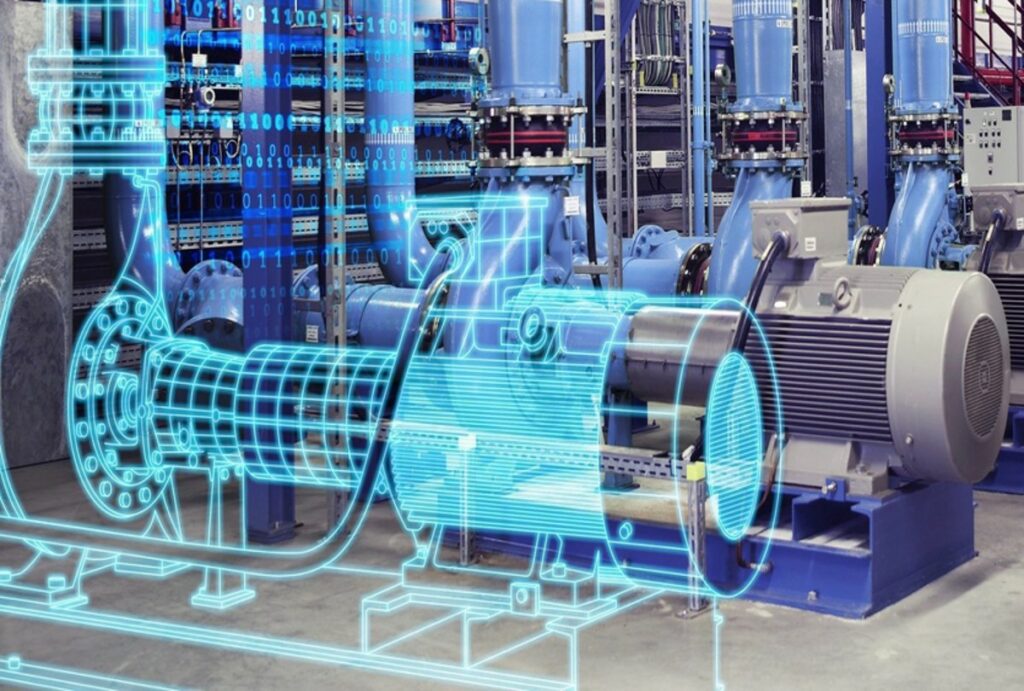

Digital twins are virtual representations of real-world physical objects using data, modelling and visualization. Digital twins are dynamic and real-time. They are much more capable than static representations like a blueprint, a schematic, a picture, a scale model or even an animation.

Read brief answers to the most important questions about digital twins below.

What is a digital twin?

A digital twin is a digital model of a physical object, such as production equipment or an oil or natural gas processing system. The physical object can be any asset, such as a natural gas compressor, a building with many systems, a locomotive, a drilling rig, or a jet engine.

Digital twin models represent all the necessary features of the physical object. The characteristics include thermal, mechanical, electrical, chemical, fluid dynamic, material, and economic properties.

What problems do digital twins address?

Some common examples of the problems that digital twins help companies address include the following:

- High equipment development cost and elapsed time.

- Unplanned equipment failures.

- High operating costs.

- High energy consumption.

- Avoidable environmental impact.

Digital twins address these problems by modelling the equipment and its operation.

What are some examples of digital twin applications?

Examples of digital twin applications include:

- Exploring design alternatives for new products or enhancements, such as downhole equipment, while avoiding the cost of building physical prototypes.

- Planning maintenance work on a complex facility, such as a gas processing plant, to minimize related downtime.

- Understanding the causes of wear and breakdowns of a physical object, such as a submersible pump, to increase the mean time between failures (MTBF).

Applications for digital twins exist in many industries, including construction, energy, healthcare, manufacturing, transportation, and utilities.

What value do digital twins produce?

As physical objects become more complex, expensive, larger and perhaps heavier, the value of digital twins increases. For example, consider the increase in the number of components in a modern drilling rig compared to its predecessor a few decades ago. Instances of how digital twins produce value include:

- Increasing throughput, revenue and profitability.

- Reducing the cost and elapsed time of equipment research and development cycles.

- Eliminating or reducing the cost of building physical prototypes or models.

- Lowering the manufacturing cost of equipment to reduce capital expenditures.

- Reducing the cost and downtime of maintenance work.

- Improving equipment efficiency and reliability.

- Improving prediction of unplanned equipment failures.

- Increasing the mean time between planned maintenance events.

- Reducing the cost and elapsed time of equipment inspections.

- Improving occupational and process safety to lower operational risk.

- Lowering operating costs while improving energy efficiency and sustainability.

- Lengthening useful equipment life.

- Improving decommissioning and recycling processes.

This wide variety of benefits is accelerating the adoption of digital twins and leading to the evolution of multiple types of digital twins.

Are digital twins simply another type of simulation?

Digital twins and simulations both utilize digital models to replicate the capabilities of physical objects. However, a digital twin is a virtual environment that adds scale and capability beyond what simulations can do. Digital twins:

- Study multiple processes concurrently. Simulations typically study one process at a time.

- Handle a real-time flow of information between the physical object and the digital twin. Simulations typically study after-the-fact data with no feedback to the physical object.

- Study more issues from more vantage points than simulations can support.

In part 2 of A quick primer on digital twins, we’ll explore the types of digital twins and implementation considerations.

About Yogi Schulz

Yogi Schulz is an information technology consultant who works extensively in the petroleum industry to select and implement administrative, operations, and geotechnical systems. He writes regular articles about developments in the energy industry and technology.

You can contact Yogi Schulz through his LinkedIn profile at this link.

Share This:

CDN NEWS |

CDN NEWS |  US NEWS

US NEWS