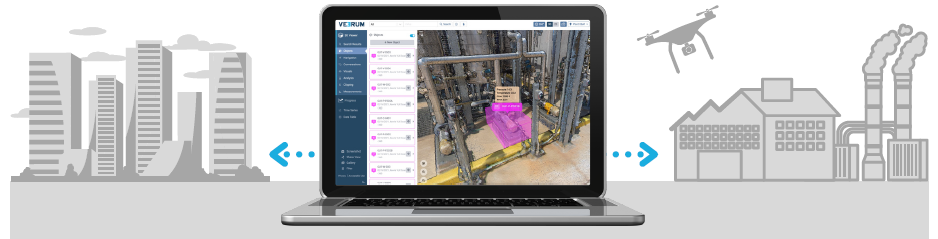

Remote legacy assets operating outside a data aggregated environment do not have a reliable tool for asset stakeholders to collaborate on for operations and maintenance activities. Maintenance planners and project teams often are working on silo’d data-sets, and constantly need to travel to site to confirm site conditions. With the cost of data capture dropping as new technology is deployed on remote assets, asset owners have the opportunity to adopt new innovative solutions to keep up with industry trends. Suppliers are often more agile and quicker to implement any advantage to improve economics, and the clients must maintain the technological pace in order to realize the benefits. Regulators are also demanding improved monitoring and data verification from the Operators which can be easily compiled, verified and reported through VEERUM’s O&M Solution.

OUTCOMES

Data aggregation

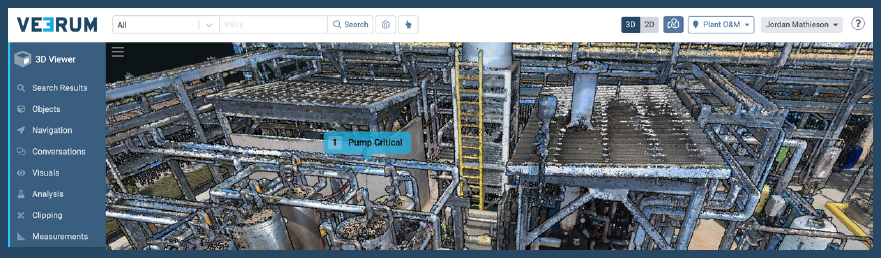

Client systems physical and virtual information in one source.

Enhanced digital experience

Remote access to all data inputs in one platform with panoramic photo navigation

Improved safety

Reduce inefficient, risky, and expensive site visits by delivering the virtual site to the entire asset team.

Unlimited users are included.

Schedule certainty

Plan and execute constraint-free maintenance plans with the collaborative digital twin tool

Prepare for AI/ML adoption

Aggregate, verify, visualize, and label your existing asset data to prepare your organization for AI/ML adoption.

Enable emergency response

Clients have 24/7 leadership coverage to ensure agile response to deviations from the Production Plan, manage emergency conditions and regulatory compliance.

VEERUM has enabled our field and office facilities planning and execution teams to collaborate more effectively by removing countless hours of calls and driving to sites for confirmations. Now, team members can co-navigate a detailed 3D visualization of a site to quickly understand current equipment, status and remotely plan for expansion or modifications. This has improved productivity while reducing our costs and unnecessary field exposure.

– Patrick Elliott , EVP Jupiter Resources

HIGH-VALUE USE CASES

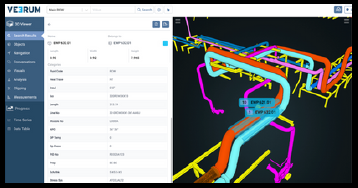

Maintenance planning

Improve workforce productivity and work quality by visualizing current site conditions. Anticipate and eliminating potential delays through remote planning and coordination of labor, parts and material, and equipment access.

Enable SIMOPS planning and execution

Single source of information for construction, commissioning, and maintenance activities to highlight and mitigate any potential restrictions and safety impacts when planning SIMOPS work activities.

Turnaround planning

Under tight timelines like turnarounds, safeguards are deemed inadequate and recommendations will be made to consider or investigate solutions to gain a better understanding of risks, and ensure no loss in production time.

Remote control operations

Reduce resources and associated costs of site-based control room operations, allowing access from higher value locations while minimizing safety exposure during planned and unplanned production scenarios.

Digital scheduling

Produce constraint-free maintenance plans, increasing time-on-tools and reducing risky site exposure hours.

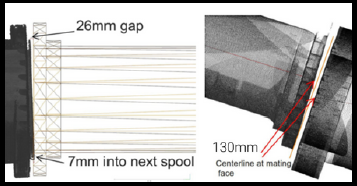

Fabrication quality assurance

Conduct dimensional precision analysis to ensure replacement components are fabricated to fit brownfield operating conditions the first time when they arrive on site.

FREE WEBINAR: How to build data-rich Digital Twins for operations and maintenance – VEERUM for Oil and Gas

When:

November 17, 12pm MST, Virtual on Zoom

Speakers:

Trevor MacMaster (CCO), Rob Southon (CTO)

Register:

Description:

VEERUM executives explore digital vs. traditional methods for operation and maintenance workflows, and how to best transition into a “digital-first” organization.

- How to move from data scarcity to abundance, solving the “data-silo” problem.

- How VEERUM works with existing investments, integrations, and trends your organization has already adopted

- How to maximize value from reality scan data and reduced surveying costs

- How to digitize your legacy facilities without the need for up to date CAD or as-built models

“You already have the information you need to get started,” says Trevor MacMaster, Chief Client Officer of VEERUM, “VEERUM’s Digital Twin visually aggregates existing asset data in a collaborative 3D viewer, and gives users tools to enrich that data over time.”

“Our goal is to democratize data in an easy, visual way that anyone can use and understand for decision making,” adds Rob Southon, CTO of VEERUM.

Join this webinar to learn how VEERUM can quickly accelerate your digital transformation journey with proven in-quarter ROI on many Tier 1 and 2 oil and gas producers. Make 2023 the year your organization goes fully digital.

This is a 2-part webinar series in collaboration with EnergyNow. Part 2 will dive deeper into industry use cases with reference clients who can answer your questions on getting started with VEERUM.

About VEERUM

Visualize and unify all your engineering, geospatial, ERP, operating, and IoT data in a single screen with VEERUM. Go live in 48 hours with the leading industrial remote work solution for operations and maintenance. Empower your team to work more efficiently, accurately and safely from anywhere in the world with access to the fastest digital twin available. Be onsite without going to site with VEERUM.

Share This:

CDN NEWS |

CDN NEWS |  US NEWS

US NEWS