AdOil Inc. is committed to protecting the environment, your reputation and your company’s bottom line. With its aluminum base and its clear poly carbonate top, the Canadian manufactured Titan wellhead containment unit has been protecting the environment from wellhead stuffing box leaks worldwide since 2001. The Titan system stops any leak, no matter how large or small, from ever entering the environment.

Why do wellhead stuffing boxes pose an environmental hazard? In actual fact, a wellhead stuffing box is designed to leak so as to self-lubricate the pumpjack polish rod. This leak is controlled by compressing the stuffing box packing onto the polish rod. However, over time packing wears out or polish rods experience mechanical damage from produced sand or chemical corrosion, and as a result the leak grows until the produced fluid flows off of the wellhead and onto the ground. Even a small leak can result in environmental issues: one drop of oil every 10 seconds equals 3.6 litres per day, 108 litres per month or 1,314 litres per year. It is estimated that at any one time 5-10% of wellhead stuffing boxes have excess leaks. A leak is cleaned up using steamers and vacuum trucks; contaminated soil is removed, disposed of and replaced with new gravel. The leak is hopefully contained on lease and does not leak into surrounding land and/or water which would have great impact both in cost and environmentally.

Protecting the Environment

A wellhead leak of is made up of crude oil and produced water. Crude oil, while biodegradable, can contain metals, naturally occurring radioactive materials (NORMS) and other toxic chemicals including well treatment chemicals such as corrosion inhibitors, biocides and emulsion breakers etc. Produced water contains various concentrations of salts that kills plants and sterilizes soils. All these contaminates remain in the soil and can migrate into the ground water with the impact on the environment being over a large area. In addition, the leak can affect local wildlife and livestock.

Protecting your Reputation

A field operator, superintendent and production/operation engineer are responsible for the safe and environmentally sound operation of the company’s wells. The larger number of wells and increased demand on a field operator’s time results in less time being allocated to each well. As a result, an operator cannot be on each location at all times to detect and correct every leak as it occurs. Even a small leak affects your reputation with local landowners, government regulators and local environmental interests.

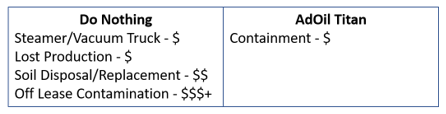

Protecting the Company’s Bottomline

Cleaning up a leak is dependent on the well’s location, availability of services, size of leak and composition of the produced fluid. Costs are related to the services to clean-up the spill, regulatory fines, lost production, labour and removal/replacement of contaminated soil. Excessive costs are associated with any migration of produced fluid off of lease. As can be seen, the Titan Containment Unit I a low cost method of stopping leaks before they become a large impact on the company’s bottom line.

AdOil Titan Wellhead Containment

The Canadian manufactured Titan Wellhead Containment Unit’s Powder-Coated Cast Aluminum Basin is designed to be installed without tools on any existing wellhead stuffing box. The containment is of rugged design with all stainless-steel fitting. UV-Resistance Polycarbonate Top is available in three sizes allowing for clear viewing and is removable for easy access. In addition, our standard install includes a High-Level Float Switch which is CSA Class 1, Div 1 approved. In the vent of an undetected leak, the high-level switch can be connected to the Presco switch for shutdown of the pumpjack or SCADA alert for your operation’s staff. An alternate sonic switch is also available.

Please contact us at [email protected], (403) 242-2201 or visit us at www.adoil.ca, to learn how we can help improve your bottom line while protecting the environment.

Share This:

CDN NEWS |

CDN NEWS |  US NEWS

US NEWS