Evaluating the hard and soft costs for oil and gas operations.

As a safety or operations manager in oil and gas, determining the best safety solution for your organization’s up-, mid-, or downstream operations is crucial. Reviewing the various features and benefits can be challenging enough, but when it comes to the bottom line, evaluating the return on investment (ROI) of safety solutions can feel daunting.

How do you put a price on workers’ health and safety?

The human cost of not having the right safety solution at the right time is something we all want to avoid. Avoiding the operational and lost productivity costs associated with safety incidents are also important when evaluating safety solutions.

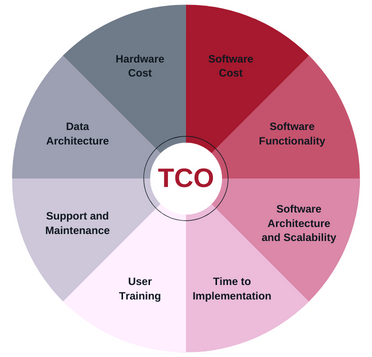

But there are additional factors to consider when determining the TCO of potential safety solutions. These can be categorized into the hard costs of the devices and consumables, and the soft costs of implementation, training, maintenance and operations.

Here we analyze the factors that contribute to TCO and how connected safety solutions can provide savings that ultimately affect your ROI.

How connected gas detection and safety saves on hard costs

For the hard costs of personal safety devices, tallying the detector’s pricing structure with maintenance equipment (e.g. bump and calibration gas) neglects critical factors that contribute to TCO. Other factors to consider include time savings from increased device functionality, overall lifespan, and reducing sunk costs from lost devices.

Oil and Gas workers face a variety of safety hazards every day, whether at refineries, or working remotely and travelling between worksites. Instead of different solutions for each unique safety hazard, consider finding a flexible and comprehensive solution that covers your workers from any hazard they may encounter.

READ MORE: How Connected Safety Proactively Reduces Risk to Oil and Gas Facilities and Workers

Multi-purpose devices

Blackline’s G6 and G7 personal wearables combine gas detection and location tracking with online analytics, reports and dashboards. G7s also include lone worker safety and communications through Push-To-Talk (PTT – like a walkie talkie) and text, allowing workers to carry a single device that serves multiple purposes.

Flexibility with Gas Sensor Cartridges

G7s can also be configured to detect one or multiple gases by swapping out the cartridge on the same device. If a worker needs to detect only H2S one day but multiple gases the following day, they can use one device and various cartridges with different sensor configurations for plug-and-play flexibility. This reduces redundancy and added training, increasing worker productivity.

Reduce Lost Devices

Using devices with location monitoring allows workers to quickly find misplaced devices – getting them back on the job fast. By mitigating lost devices combined with a longer lifespan, using Blackline’s G6 and G7 personal wearables also means you’ll reduce the need for extra inventory.

How connected safety saves on soft costs

There are hidden soft costs of gas detectors that if considered in your TCO analysis can reveal some serious upside of choosing connected devices.

Reduce Maintenance Costs

Looking at maintenance, gas detection devices need to be kept in compliance through regular bump testing and calibration. This often falls to third-party service providers, not only incurring costs but taking the devices out of service for a period of time. Blackline’s single- and multi-gas detectors use an efficient docking system that empowers individual workers to bump test and calibrate their own devices. This renders a third-party and additional IT infrastructure unnecessary to remain compliant. You can also confirm the status of all devices in the online portal, dashboards and reports to ensure workers are fulfilling requirements to keep their device compliant.

Reduce False Alarms

False alarms can be relatively frequent with conventional safety devices, resulting in costly and unnecessary evacuations. This can lead to worker complacency, such as ignoring or turning devices off, increasing the risk of safety incidents. You also don’t need to wait for the devices to be docked to download critical information – adding efficiencies that save time and costs.

Eliminate IT Set-up Requirements

Initially, you may think that using connected safety would require a draw on IT, but the opposite is true. Setting up and maintaining IT infrastructure (such as mesh networks) takes resources and time, translating into indirect soft costs that affect the TCO of your safety program. Using cloud-connected devices negates all these costs and enables automatic, over-the-air settings and configuration changes, removing the need to dock the devices for firmware updates.

Improve Evacuation Management Process

Because connected devices provide worker location in real-time via an online portal, manual headcounts aren’t necessary, increasing worker safety. Instead of having to send out search parties, workers’ precise locations are known, and rescuers can go directly to where help is needed. This not only saves precious time in an emergency evacuation when lives are on the line but greatly reduces drill times as well, allowing workers to return to the task at hand – increasing productivity.

READ MORE:

Leave No One Behind: How connected safety technology streamlines evacuation management

Conclusion

Using a flexible, comprehensive connected safety solution mitigates the need for multiple devices and extra inventory, reduces IT resources and operational churn, and cuts down on training and change management – all lowering the TCO of your safety program.

We hope this review of the hard and soft costs that contribute to the overall TCO has been helpful as you evaluate options for your gas detection and lone worker safety needs.

For additional oil and gas safety resources, CLICK HERE.

Learn more:

Watch G7 Videos

Share This:

CDN NEWS |

CDN NEWS |  US NEWS

US NEWS

COMMENTARY: Where the Fight Against Energy Subsidies Stands – Alex Epstein