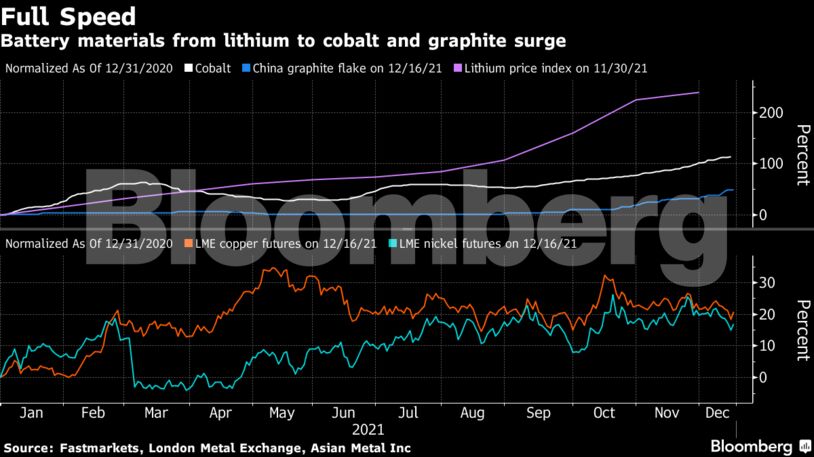

Battery metals are in the throes of an unprecedented boom as the global push toward a greener future fires up demand for materials such as lithium, cobalt and nickel, at a time of constrained supply exacerbated by the pandemic. That will probably boost battery costs and could delay the widespread adoption of electric cars. Now the omicron variant is complicating matters even more.

“The new Covid-19 variant has thrown a cog in the wheel of the global recovery,” said Kwasi Ampofo, head of metals and mining at BloombergNEF. “We expect the supply-chain constraints that impacted the movement of materials this year to remain well into 2022.” Prices of lithium, graphite and cobalt are likely to stay elevated, potentially easing only in 2023, he added, though nickel could see a decline in prices by the second half of next year.

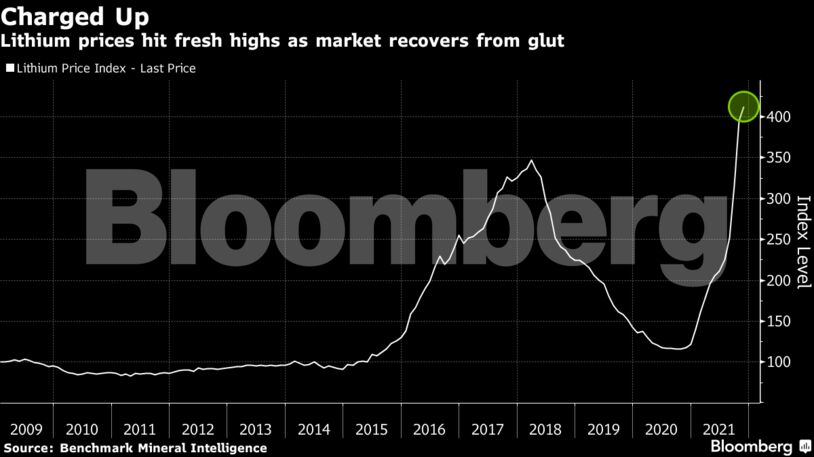

Lithium Record

An index of lithium prices has more than tripled this year to a record. Chinese producer Chengxin Lithium Group expects prices to “stay at relatively high levels for a while,” bolstered by buoyant downstream consumption and constraints in brine production capacity and spodumene supply. “It’s hard to see any material changes in global market tightness in the short term,” the company said in a written response to Bloomberg News.

Green exuberance has tightened the lithium market this year after years of underinvestment when prices were sluggish. As miners scurry to expand capacity, long-term electric-car demand bodes well for the material that’s used in virtually all EV batteries. Passenger electric-car sales are projected to soar from 3 million in 2020 to 66 million in 2040, according to BloombergNEF’s Economic Transition Scenario.

“We expect global average lithium prices to continue increasing over the next couple of years as contract prices start catching up to spot and as supply continues to be unable to reach demand,” said Cameron Perks, analyst at Benchmark Mineral Intelligence. “A balanced market is not projected until 2025 or 2026 at which point prices may start to subside.”

Cobalt and Nickel

Cobalt has doubled in price this year. The metal’s been grappling with supply chain disruptions in South Africa — which exports the majority of global cobalt supply out of the Democratic Republic of Congo, according to Alice Yu, an analyst at S&P Global Market Intelligence. Omicron risks worsening logistical challenges, and could delay the timing of a price correction, she said.

Still, the outlook is not all bullish. “The supply side has ramped up cobalt production capacity and that could come online next year,” said Wang Wentao, general manager of trader Shanghai Qin Cobalt Industrial Co. The commodity market could also be engulfed by a risk-off mood among investors as central banks begin to raise interest rates, he added.

Nickel has jumped about 17% this year, but aggressive supply expansion from Indonesia could swing the market into a surplus in 2022, according to S&P Global Market Intelligence. Prices took a hit in early December after Tsingshan Holding Group Co. said it’s operating its first production line for nickel matte, an intermediate product that can be processed into battery-grade chemicals.

Graphite prices have climbed sharply since September amid power curbs in China, the world’s biggest producer of the anode material. “With the expected increase in power demand this winter, power supply may be tight, and production of flake graphite therefore may not fully recover until the first half of 2022,” according to a BNEF report.

Higher Costs

A large chunk of the cost of a battery — the most expensive part of an electric car — is tied to commodities that have rallied this year. In China, the world’s biggest electric vehicle market, battery manufacturers have already started to feel the pinch from the escalating cost of raw materials.

SVolt Energy Technology Co., which has an agreement to supply Jeep-maker Stellantis NV, has already flagged issues with materials including copper foil, while Gotion High-tech Co., a partner of Volkswagen AG, told customers in mid-October it needed to raise battery prices.

Battery costs are on course for the first jump since BloombergNEF began tracking them in 2012, which is set to deal a blow to the automotive industry. Electric vehicles are expected to reach price parity with petrol and diesel cars when a battery pack drops below $100/kWh, but higher raw-material costs could delay that by two years to 2026, according to BloombergNEF.

Share This:

CDN NEWS |

CDN NEWS |  US NEWS

US NEWS

COMMENTARY: Where the Fight Against Energy Subsidies Stands – Alex Epstein