An analyser array supports corrosion management through continuous insights into changes in crude quality

By ALBERT MOURIS and ETIENNE HUNT Hobré Instruments

KEVIN CLARKE CREAS Energy Consulting

To maximise profits and remain competitive, refineries regularly reoptimize their crude slate with changing market conditions. As a result, crudes change frequently, and the plant is driven towards processing cheaper, heavier, and lower quality crudes. Many of these lower quality crude oils contain higher levels of salts (chlorides), organic chlorides, sulphur, nitrogen, metals, tramp amines, as well as high solids and acidity. All of these factors can drive up corrosion within the crude processing complex without proper conditioning which, in turn, can be hampered by the difficulty in determining the precise crude mix hour-by-hour (inadequate tankage for proper segregation, layering, tank heels of unknown composition, slops reprocessing, tight crude oil inventory controls to minimise working capital, and the frequency of crude tank changes). Many refiners report crude changes as often as every two to three days.

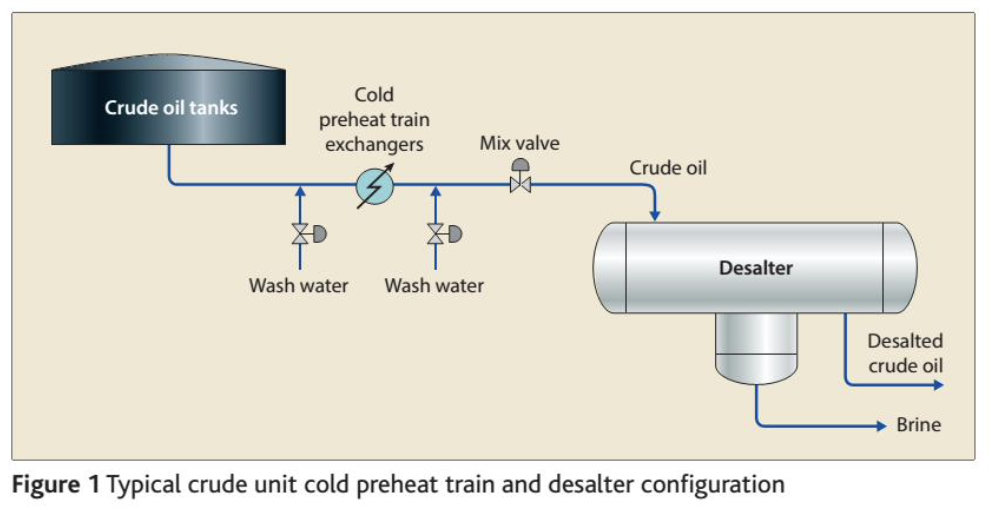

A critical element of corrosion control within the crude complex is the desalter (see Figure 1). The desalter serves several purposes:

- Reduces the salt (inorganic chloride) content of the crude oil

- Dehydration

- Solid separation

- Recovery of phenols from wastewater

Salt occurs naturally in crude oil, so a certain amount of brine is produced with crude which is separated in the field and relatively dry crude oil is sent to the refinery. Chlorides introduced into an oil well during a workover or well stimulation will also appear in the produced crude. Salt can also enter crude oil from seawater during transportation. The salts in crude oil consist primarily of sodium, magnesium, and calcium chlorides.

While some of these lower quality crudes can be priced at a $2-$3/ bbl discount to Brent, most refiners would not be able to process these at more than 25% of their total crude slate – implying a commercial incentive of approximately $0.50-$0.75/bbl or $37-55 million/y for a typical 200000 b/d refinery. Recent studies have suggested that the annual cost of corrosion in refining is approximately $15 billion or $0.45-0.50/bbl of total global crude oil processed. Processing of these lower quality crude oils is concentrated within a subset of the global refining population, so there is clearly considerable commercial risk to processing these crudes without adequate monitoring of contaminants, operations, and corrosion rates to mitigate the potential for integrity problems.

Magnesium and calcium chlorides have a higher tendency to remain in the oil phase than sodium chloride, so sodium chloride removal by effective desalting is usually nearly complete. In most cases, magnesium and calcium chloride levels in crude are low.

As crude is processed through the crude tower and then the vacuum unit and downstream residue upgrading units such as delayed cokers, residual magnesium or calcium chlorides will hydrolyse in the presence of trace water, releasing hydrogen chloride. The hydrolysis to temperature relationship is illustrated in Figure 2.

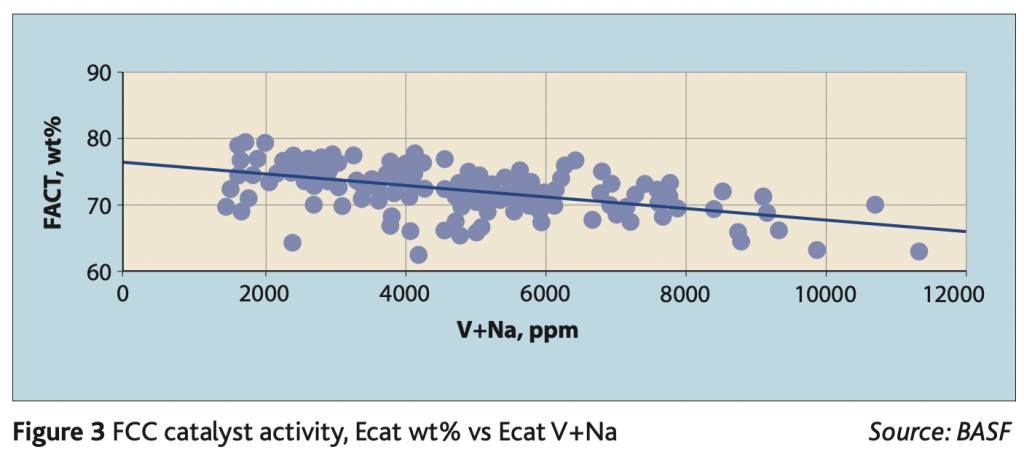

Sodium chloride will not decom- pose to any significant extent but passes into the atmospheric residue where it can accelerate coking in the vacuum unit and downstream residue conversion units (visbreaker, delayed coker, and so on), shortening the run length between heater decokes. In addition, sodium in the FCC feed serves to exaggerate the conversion impact of any vanadium in the FCC feed, with implications for fresh catalyst use and yield performance (see Figure 3).

Hydrogen chloride generated from the magnesium and calcium salts will move upwards in the distillation columns until it finds ammonia or amines to combine with, or until a liquid water phase forms, or until the hydro- gen chloride is drawn into a product. The corrosive impact of the chlorides will then be observed in the crude tower and the overhead heat exchangers. Therefore, good control of the desalter can substantially reduce corrosion within the crude tower overheads, as well as fouling in the pre-heat exchanger train and oil con- tent of the desalter effluent water. However, many refineries have increased processing capacity over time and are running a progressively heavier crude slate, without making the corresponding modifications to their desalters, with the result that de-salting and dehydration efficiencies have declined, thereby driving up the risk of downstream reliability issues.

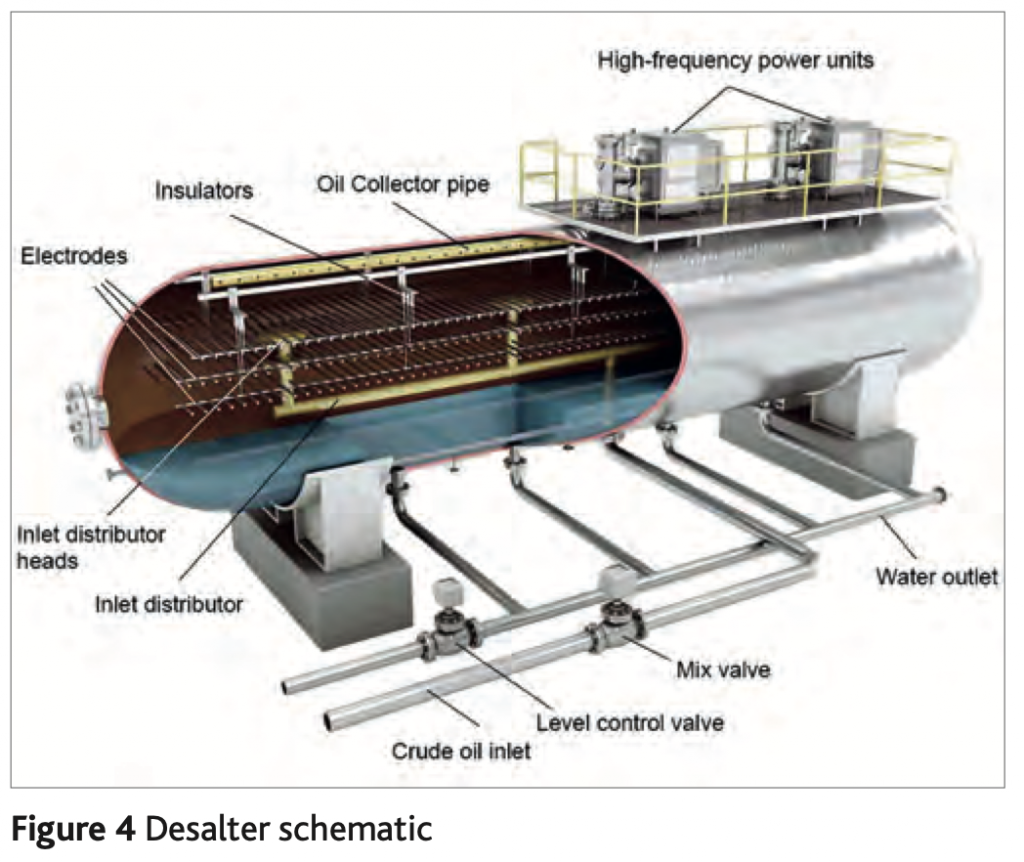

In addition, normal build-up of sediments in the bottom of the desalter during the run (see Figure 4 for typical desalter internals) can also serve to reduce residence time, so desalting efficiency can reduce across the cycle. Within these tight net margin environments, it is sur- prising that the operation of many crude oil desalters is not rigorously adjusted following changes in the crude slate, and there has been limited investment in tracking desalter operating performance in real- time to provide advance warning of sub-optimal performance and potential downstream issues.

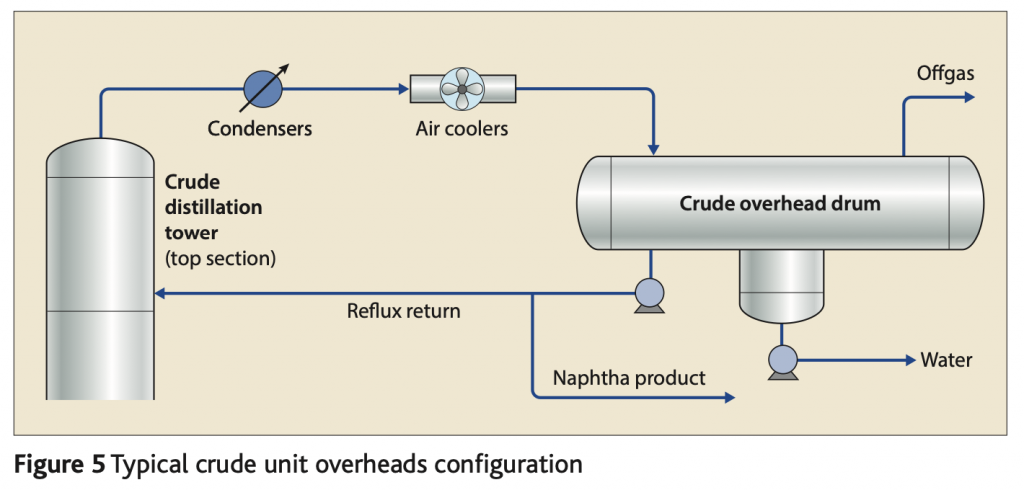

Clear understanding of the chloride content of the desalter effluent crude oil is therefore critical to mitigating corrosion. Chlorides (NaCl, MgCl2 and CaCl2) in excess of 20 ppm are known to cause serious corrosion issues due to the liberation of chloride ions which travel to the top of the crude tower (see Figure 5) and condense with the first drop of water at the water dewpoint, with a very low pH (1-3). This highly localised point of corrosion can move around within the overhead system, depending on the water content, top temperature, functioning of the condensers, and vapour flow rate. Refiners inject ammonia or amines into the over- head system to neutralise the acid, as well as filming amines which cover the internal surfaces of the exchanger tubes to prevent the acid from reaching the metal surface. Frequent crude changes and variations in desalter performance can result in under-dosing of neutralising amine. Filming amines can also be stripped by high vapour velocities or may fail to coat all surfaces evenly. As a result, dewpoint corrosion remains an ongoing issue within many crude towers.

This difficult situation is further exacerbated by two other factors:

- The declining demand for gasoline, particularly in European and Asian economies where refiners typically aim to maximise middle distillate (jet fuel and diesel) pro- duction. This drives down the optimum temperature for the crude tower overhead, further raising the risk of dew point corrosion, as well as the exposure of larger areas of the crude overhead system to the potential of dewpoint corrosion, such as the tower dome itself.

- Presence of organic chlorides in the crude oil, from upstream oil production chemicals, particularly with ageing oil fields. Organic chlorides are not removed in the desalter, preferring to remain in the oil phase, but can release chloride ions in the crude distillation tower just the same. These chloride ions usually appear in the naphtha streams and react in the naphtha hydrotreater(s) to release hydrogen chloride, causing corrosion and fouling problems. The contamination of the Druzhba crude oil pipeline network with organic chlorides in April 2019 is a case in point which caused severe disruption to refinery operations in Central and Eastern Europe.

Real-time corrosion management

Good single-stage desalter performance achieves a desalting and dehydration efficiency of more than 90%. More than 95% salt removal can be achieved with double de-salting. Absolute performance depends on various key parameters such as:

- Crude oil properties (API, asphaltene content, and so on)

- Desalter temperature Desalter pressure

- Wash water pH

- Oil residence time

- Effectiveness of the demulsifier chemical

- Wash water mixing

With relatively low levels (>20 ppm) of chloride content in desalted crude having the potential to lead to significant corrosion issues in the overhead condensation system of the crude distillate unit (Palash Kumar Bhowmik, 2012), the Hobré solution employing the C-Quand XRF analyser comes into play. The C-Quand XRF analyser provides on-line measurements of crude contaminants (such as total chlorides, sulphur, magnesium, iron, nickel, vanadium, arsenic, and other elements) to enable the realisation of a real-time corrosion management strategy for the crude distillation unit, by:

- Ensuring effective crude desalting, by enabling reporting of desalting efficiency in real-time and alerting any exceptions caused by performance degradation during and following crude switches or due to slops reprocessing (with an undetermined and highly variable chloride content).

- Alerting to changes being required in overhead chemical dosage (ammonia or neutralising amines and filmer) by real-time measurement of the chloride content in the overhead water. This enables tighter tracking of chemical injection rates in case of unit upsets, fluctuations, during start-up, or processing of crude oil with high organic chloride content.

- In addition, real-time measurement of metals in crude oil can bring considerable value in predicting imminent changes in downstream unit feeds, where contaminants are either poisons or key final product quality specifications (such as chloride load to naphtha hydrotreating units, FCC feed nickel, vanadium, iron or delayed coker feed nickel, vanadium, sulphur). The system can also provide insight into incoming iron in crude, which is a problem widely observed during processing of light tight oils, to enable optimisation of iron removal chemicals.

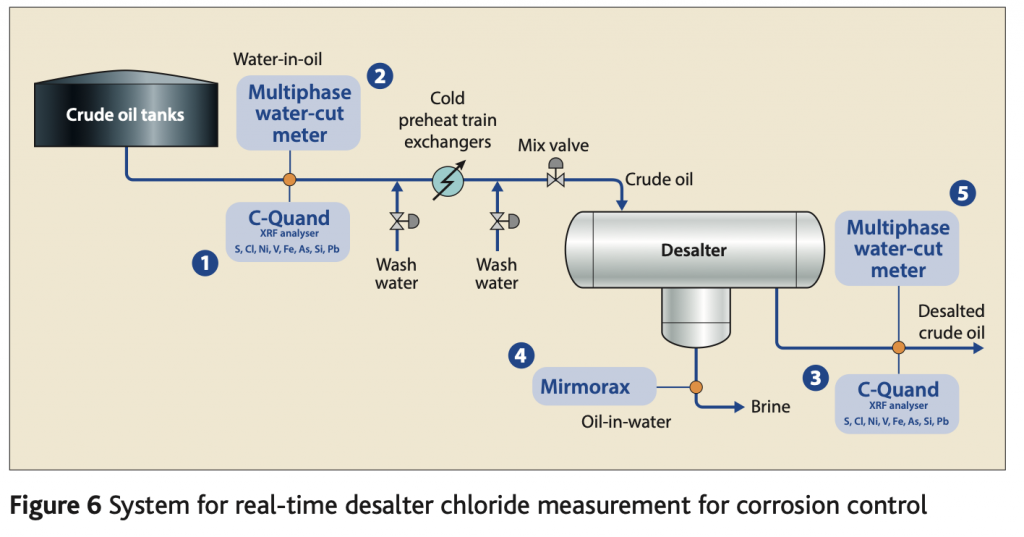

With over 55 years’ experience in designing and engineering online process analysers, Westech Industrial offers turn-key total package solution using Hobré Analyzer Solutions which will be tailored to specific layouts. The proposed solution consists of a set of C-Quand ED-XRF non-destructive analysers (and optionally sample handling, shelters, and additional measurements for oil-in-water and water-in-oil analysis), providing the measurement of chlorides in real-time, offering the potential for continuous corrosion control (see Figure 6).

By accurate, sensitive, and continuous measurement upstream (Position 1 in Figure 6) of the desalter, the analyser enables operators to track changes in total chlo-\ride levels, to proactively adjust desalting operating conditions and chemical addition rates to ensure good desalting and dewatering performance.

A second analyser downstream of the desalter unit (Position 3) tracks the desalted crude chloride content to verify desalting performance and minimum chloride entering the crude tower.

For systems employing double desalting vessels, the desalted crude C-Quand analyser in Position 3 could be multiplexed to measure chloride entering the second desalter.

To provide a complete picture of desalter performance, installation of a water-in-oil analyser at Position 2 provides early warning of excessive water levels coming from crude tankage, in the event that the crude oil has not had sufficient settling time. Operators can use this measurement to anticipate an increase in water by trimming the wash water rates to avoid over- loading the desalter and could be incorporated into a closed-loop control scheme.

A second water-in-oil analyser is proposed for the desalted crude (Position 5) to ensure that the unit is performing to optimal dehydration levels. Next, an oil-in-water analyser is recommended for the desalter effluent water (‘brine’) to ensure that this is minimised (Position 4), to avoid losses of crude oil to the effluent water treatment system that then consume crude processing capacity when they are later reprocessed.

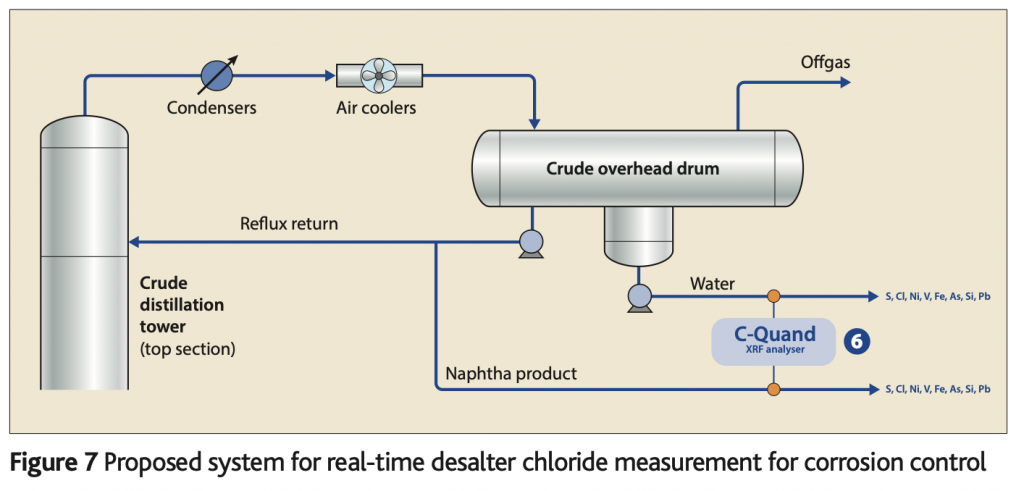

Finally (see Figure 7), a C-Quand analyser measuring the chloride content of the crude overhead drum water (Position 6) enables real-time tracking of chloride excursions and, particularly, any organic chloride breakthrough, providing guidance to optimise filming and neutralising amine dosages. In addition, the analyser provides measurements of metallic corrosion products such as iron. This analyser can be multiplexed to also survey chlorides in the naphtha product, to provide early warning of carry-over into the naphtha hydrotreater feed. Tighter understanding of the total chloride balance across the desalter and the tower overheads, in combination with an on-line overhead corrosion monitoring system, allows opera- tors to drive the top temperature to a minimum, thereby driving up commercially attractive middle distillate yields at the expenses of naphtha/ gasoline, without unnecessarily risking increased corrosion rates.

Economic justification

For a mid-sized refinery of 200 000 b/d, the estimated annualised costs due to a crude overhead failure caused by corrosion alone are of the order of $1.5 to $3 million/y (five- year run between turnarounds). A single 10-day shutdown event would cost approximately $6-11 million in lost processing capacity, replacement equipment (often ordered at short notice with premium pricing for rapid delivery), subcontract personnel, staff over- time, and crane costs. This figure would be further increased by an amount of the order of $7 million/y, comprising:

- Reduction in crude tower over- head temperature (≈0.5°C) to increase jet kerosene production by 0.1 vol% (at the expense of naphtha) without increasing the risk of dew point corrosion (≈$8.5 million/y for a 200 000 b/d refinery)

- Demulsifier over-dosing costs (≈$31k/y for a 10% saving)

- Filming and neutralising amine over-dosing costs (≈$10,700/y for a 10% saving)

- Preheat exchanger network fouling increasing energy costs and/or increased preheat train antifoulant dosage (≈$462k/°C/y)

- Costs for reprocessing of recovered oil from effluent water treatment (≈$462k/500 b/d/y)

- Savings in laboratory analysis, equipment and consumables costs (≈$150k/year)

- Impact of chloride carry-over into the naphtha hydrotreater feed from corrosion, heat exchanger fouling, catalyst fouling and deactivation, and increased reactor pressure drop (not evaluated)

- Shorter run lengths between heater decokes on the vacuum heater and any downstream residue conversion units (not evaluated)

- FCC yield impacts from higher Na+V in the feed, requiring higher fresh catalyst addition to restore yields, and/or economic penalty from yield degradation (≈$150k/ year for a 1% increase in fresh catalyst usage)

A fully installed and operating analyser system, as specified in Figures 6 and 7, would generate a payback within just two to three months of operation, based on the operations savings evaluated above. A much shorter payback would be achieved if the system prevented an unplanned shutdown caused by crude overhead corrosion.

Further Information

For more information on Westech Industrial’s Hobré Analyzer Solutions and the C-QUAND please visit our website at https://westech-ind.com/brands/hobre/or call and speak to a technical representative at 1-800-912-9262.

Addition Reading

C-QUAND is a mark of Hobré Analyzer Solutions.

Further reading

1Xiaohui Li BW, Hazards of Organic Chloride to Petroleum Processing in Chinese Refineries and Industrial Countermeasures, Progress Petrochem Sci .2, 2018.

2 American Petroleum Institute, Understanding crude oil and product markets, Digital Media, 2014.

3 Palash Kumar Bhowmik M E, Corrosion and its control in crude oil refining process, Dhaka: IMEC&APM- ABS-000, 2012.

Share This:

CDN NEWS |

CDN NEWS |  US NEWS

US NEWS