By Robert Brown with contributions by Chuck Becht V

In this difficult era of decreased margins and rapidly changing markets, onstream reliability is critical to the success of operating facilities. Achieving high onstream reliability can be particularly challenging for complex systems like a CATOFIN® Unit. The CATOFIN® Unit pairs extremely high operating temperatures with a complex control system interaction of instrumentation, valves, compressor train, and gas turbines. The mechanical design must overcome multiple damage mechanisms (e.g. elevated temperature creep, fatigue due to thermal cycling, creep-fatigue interaction, material property degradation, etc.) The instrumentation and control system side must be strategically set up to avoid frequent spurious trips which can exacerbate the severity of the mechanical damage mechanisms. Becht has extensive experience in re-designing bad actor units and success with instituting reliability improvements for these complex systems. We utilize a multi-disciplinary approach to determine root causes and establish practical modifications for improved performance. This article focuses on our approach to address reliability issues with CATOFIN® units specifically, but the principles can be applied to other units with challenging service conditions.

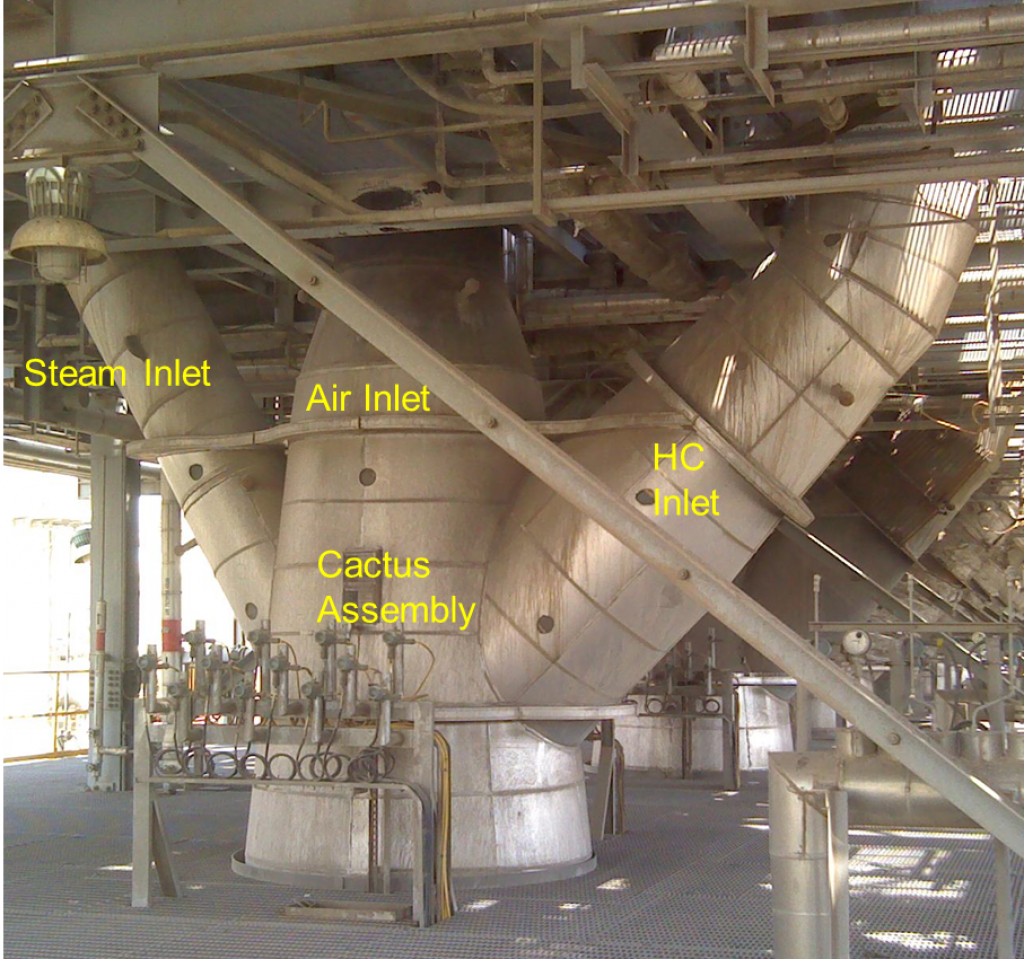

The CATOFIN® licensing technology is a process for propane dehydrogenation (PDH) that is employed at numerous facilities worldwide. Licensed by Lummus Technology, it is a process for production of olefins, such as propylene (from propane) and iso-butylene (from iso-butane). This is a continuous PDH process that uses sequential cyclic operation of multiple fixed-bed reactors through automated programming to control the key phases of the process. The unit employs large diameter main piping headers for the air and hydrocarbon (HC) inlet and outlet circuits (see Figures 1 and 2), as well as components called cacti that connect to each reactor and multiple piping branches (see Figure 3). The headers operate at relatively low pressure or vacuum conditions, but relatively high process temperatures on the order of 570°C (1060°F) to 705°C (1300°F), depending on the region of the system. The headers are hot-walled configuration, type 321H SS and employ numerous bellows type expansion joints due to the significant thermal growth at these temperatures. Regions of the cacti are typically cold-walled (refractory lined) and transition to hot-walled in some designs, with 310H SS material transitioning to low chrome on the HC and steam branches.

Figure 1: Cactus Assembly Typical to Each Reactor

Click here to read the full blog

Share This:

CDN NEWS |

CDN NEWS |  US NEWS

US NEWS