By Magnus Gustafsson

Why do outlet collectors only rarely fail, even when subjected to pressure-drops well above the design basis of the collector? The answer lies in the design approach which incorporates simplifying assumptions to accommodate a tractable and conservative approach. These conservatisms can be relaxed where necessary to give results much more in line with actual experience while still maintaining an appropriate amount of margin.

The outlet collector (aka “elephant stool”) of a reactor is subjected to loads from the weight of the bottom catalyst bed and the live load, i.e. pressure-drop over the bed. Collectors are designed to withstand the full magnitude of these loads with a margin applied to protect against buckling of the collector. A failure of an outlet collector typically results in catalyst loss and can cause an unplanned shutdown to repair, which requires dumping of the catalyst.

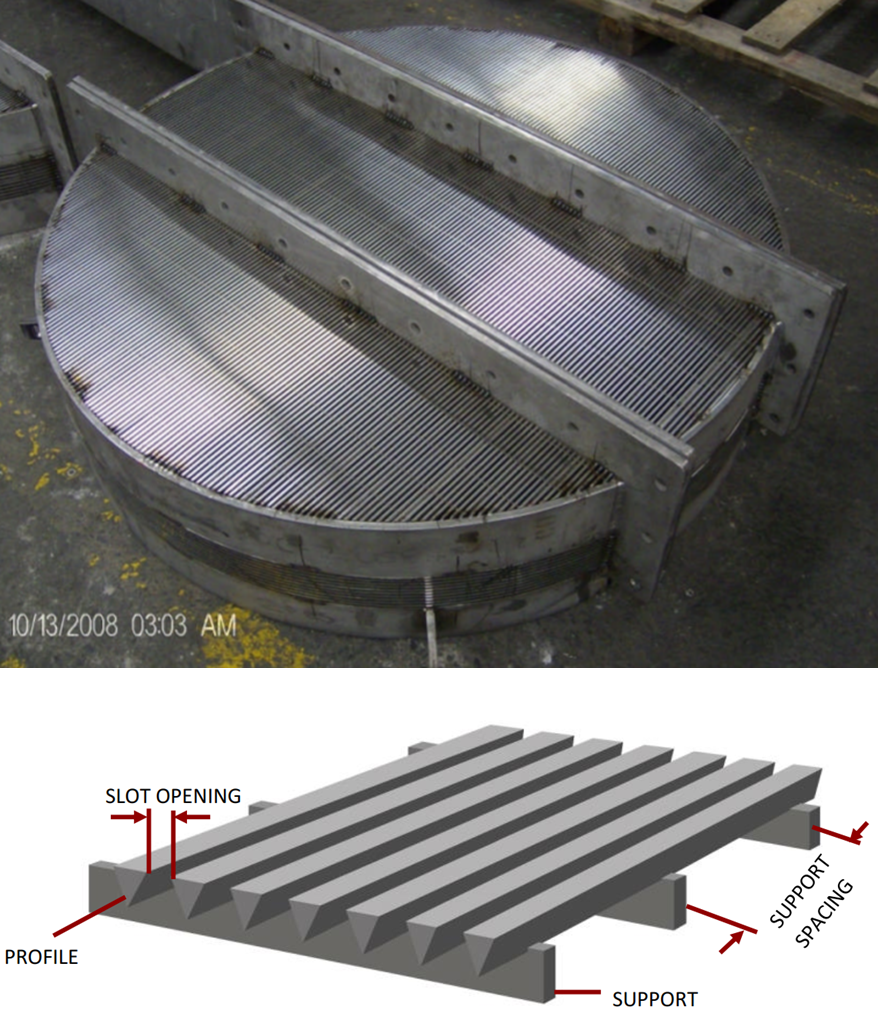

Becht receives requests to evaluate outlet collectors because the allowable pressure-drop, usually defined with simplifying hand calculation methods, is exceeded due to catalyst bed fouling near End-of-Run (EOR) causing the live load to increase over the design basis. In most of these cases, we assess the outlet collector for the predicted maximum pressure-drop through a buckling analysis with a Finite Element Analysis (FEA) model that takes into the account the actual geometry of the collector. Collector geometries can vary greatly and include an assembly of structural components made of plate and rings that have slots or are covered with mesh screen to support inert material and catalyst beds. Figure 1 shows an example of an outlet collector configuration.

Figure 1: Example Outlet Collector Configuration

Click here to read the full blog

Share This:

CDN NEWS |

CDN NEWS |  US NEWS

US NEWS