A flow meter with 400 CPM of NORM radiation embedded in the metal was safely decontaminated to background levels of radiation after FQE® NORM-Clear™ was applied

Results Achieved

- Successful removal of radiation embedded in metal and scale

- Radiation reduced to safe background levels from 215-400 CPM

- Reduced cleaning time over manual methods

Chemicals Utilized

FQE Scale-Solv

Effective in the cleaning of scale such as barium sulfate, silicates, and various other scale deposits.

FQE NORM-Clear

Patented product for the removal of NORM contamination equipment.

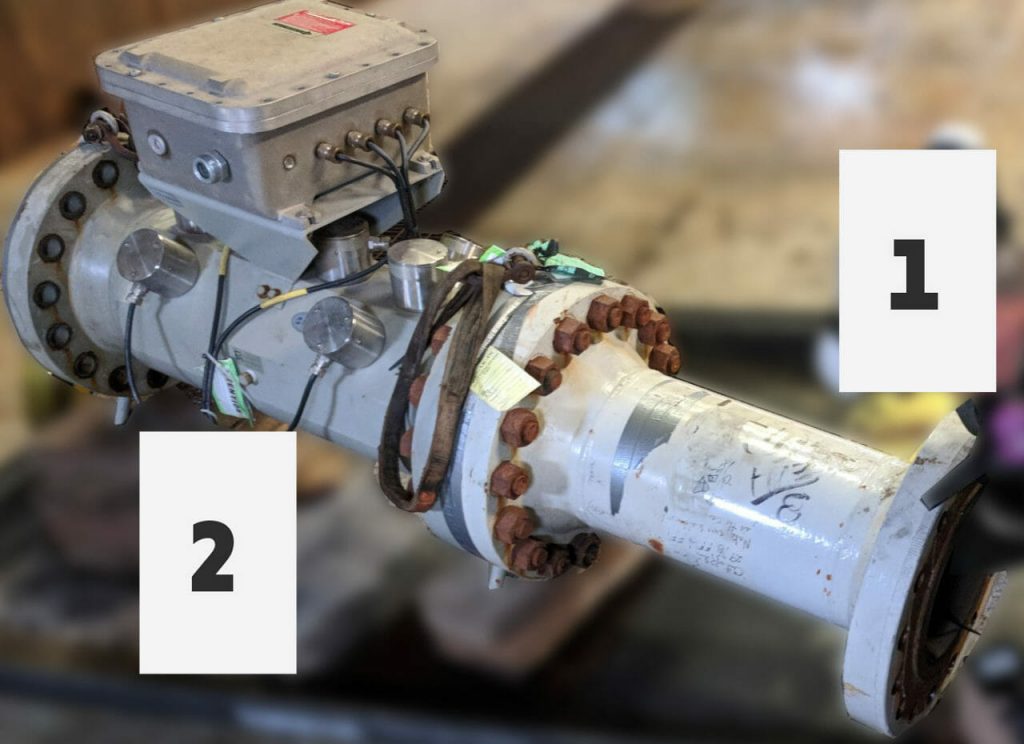

Flow Meter Before (Left: 215 & 400 CPM) and After (Right: 80 & 100 CPM equal to background radiation) using FQE NORM-Clear

In October 2019, a large facility in Alberta reduced NORM radiation counts per minute (CPM) to the allowed occupational limits in the field with FQE NORM-Clear in order to operate contaminated equipment.

The facility had tried sandblasting and hydroblasting in the past to try and remove NORM radiation from equipment. Since NORM embedded in metal cannot normally be removed using mechanical methods, this did not produce reliable results and the process required removal of equipment from operations.

Before the chemical decontamination treatment, the equipment was measured in two separate hot spots using a Geiger counter. The spots registered at 215 CPM and 400 CPM. For the application to be successful, the NORM radiation levels must be reduced to below 190 CPM.

Hot Spot Geiger Counter Measuring Points on the Contaminated Flow Meter

To remove the NORM contamination embedded in the metal, FQE Scale-Solv was circulated to remove the scaling and buildup on the walls of the equipment.

Then, the patented chemistry FQE NORM-Clear was circulated for only 6 hours. It was found that this method did not cause corrosion, erosion, or undue damage to the flow meter or any of its’ integral components.

After circulation and treatment was complete, the hot spots were remeasured and were effectively reduced to 80 CPM and 100 CPM, which is the background radiation level at the site.

Learn more about FQE Chemicals by visiting: fqechemicals.com

Share This:

CDN NEWS |

CDN NEWS |  US NEWS

US NEWS

COMMENTARY: Fossil Fuels Show Staying Power as EU Clean Energy Output Dips – Maguire